Uncover the secret of angle grinder accessories: ultra-thin cutting plate, grinding wheel plate and polishing plate

In modern industrial manufacturing and home maintenance, angle grinders have become one of the indispensable tools. However, few people know that its true power comes from a series of efficient accessories-ultra-thin cutting plates, grinding plates and polishing plates. These seemingly ordinary parts actually carry an important mission, which not only improves the efficiency of work, but also greatly improves the safety and quality of operation.

Each accessory has unique functional characteristics and is suitable for different types of tasks. For example, ultra-thin cutting plates are used to precisely cut metal and other hard materials; grinding plates are good at removing surface imperfections and performing rough grinding; and polishing plates are ideal for the pursuit of perfect smoothness. With the advancement of technology, these components hide more and more complex technical principles and development processes, let us enter the world of professional polishing together.

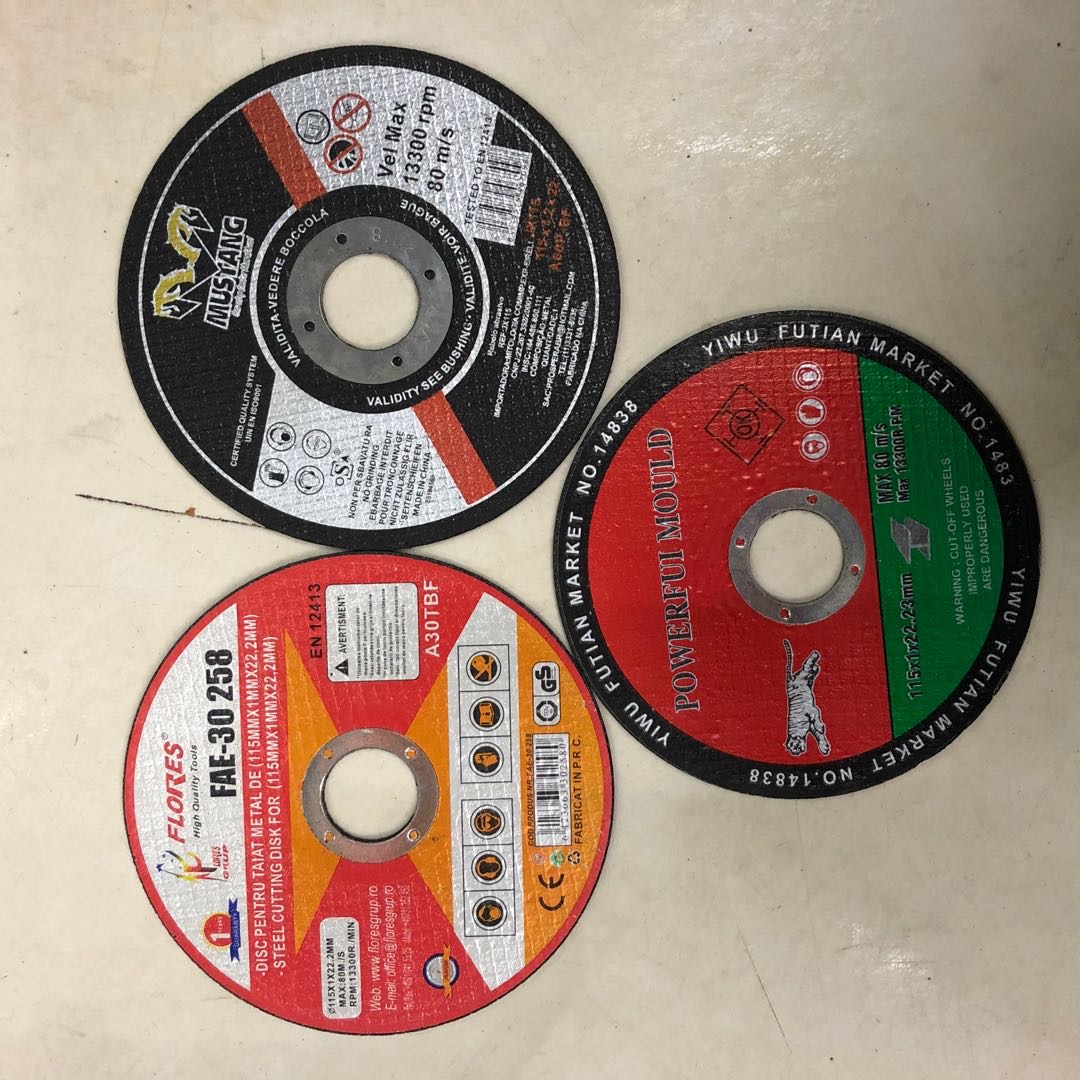

Angle Grinder Common Accessories Combination Display

Angle Grinder Common Accessories Combination Display

The power of precise cutting: the advantages of ultra-thin cutting board

When we say "ultra-thin", it means that this cutting board has the ability to surpass regular. It is made of a special alloy material with a thickness of only a few millimeters or less, which makes it flexible to use in small spaces and can achieve extremely fine incision widths. Whether it is stainless steel pipe or tile stone, in front of this efficient weapon will become easy.

Many user feedback pointed out that the use of ultra-thin cutting board can not only greatly shorten the working time, but also effectively reduce the frequency of blade wear. According to the laboratory measured data, compared with the traditional thick plate, the average life of the new ultra-thin model has increased by nearly 30%, greatly reducing the replacement cost. At the same time, because the edges are sharper and smoother, it is also easier to obtain a satisfactory finished appearance.

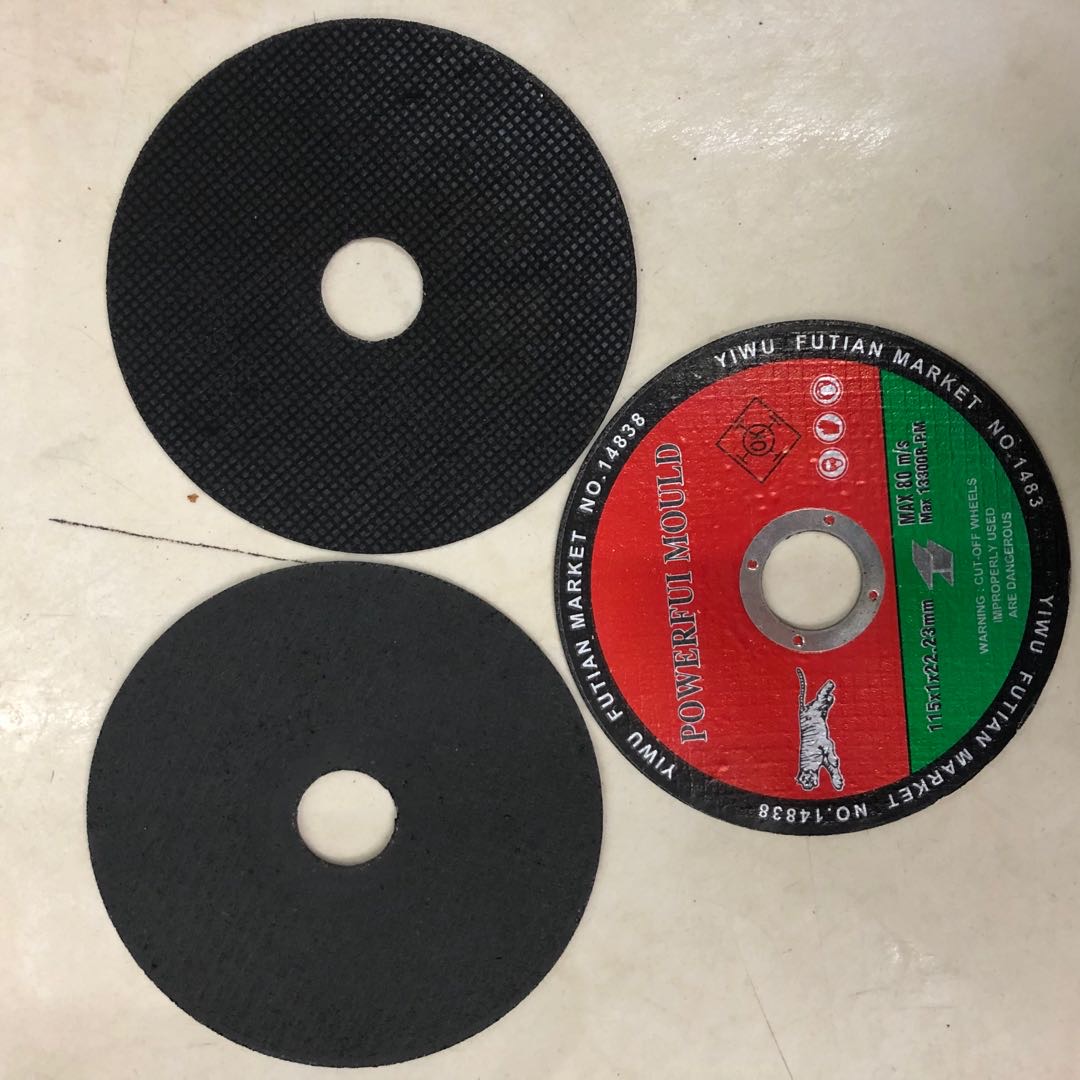

Application example of ultra-thin cutting board

Application example of ultra-thin cutting board

The tough and wear-resistant guardian: the core value of the grinding wheel plate

If the ultra-thin cutting board focuses on precision, then the grinding wheel board is born for speed and strength. It is usually composed of high-strength ceramic particles or other wear-resistant substances, which can remove a large amount of material surface impurities in a short time and restore the original luster and flatness. Even in the face of rough or stubborn stains can also perform well.

It is worth mentioning that the high-quality brand of the grinding wheel plate uses an advanced binder formula to enhance the close bonding force between the various parts, so that the entire product structure is more solid and stable. In contrast, some cheap substitutes on the market are prone to fall off, which seriously affects work efficiency and even causes safety hazards. In addition, some high-end models are also equipped with automatic cooling systems to prevent deformation and damage caused by high temperatures, further extending the service life.

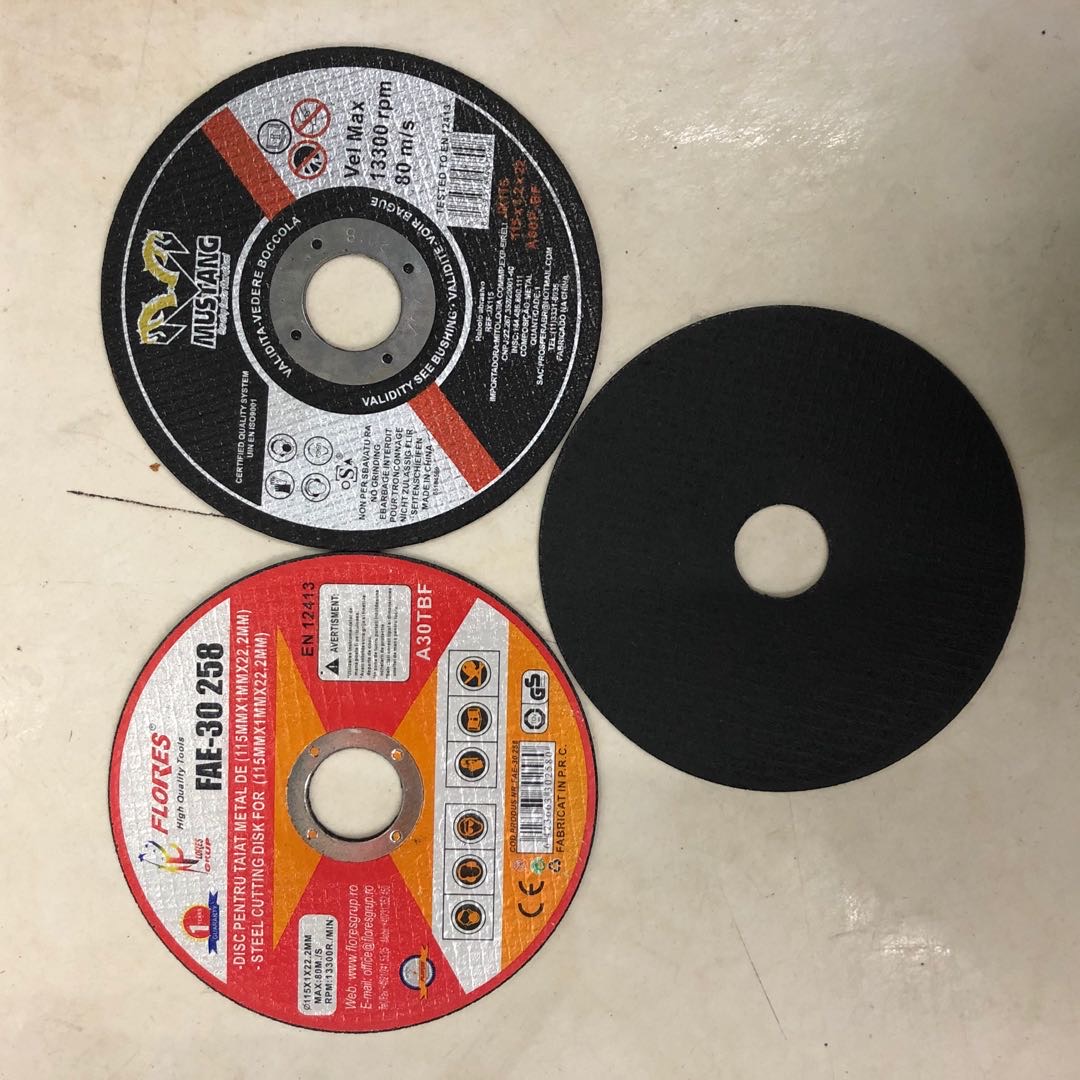

Schematic working principle of the grinding wheel plate

Schematic working principle of the grinding wheel plate

The pursuit of perfect smoothness: polished board brings unparalleled quality experience

For many handicrafts or mechanical parts, only relying on pre-processing cannot achieve the ideal state. At this time, it is necessary to use professional polishing equipment to carry out the final polishing treatment. And the most critical role is the polishing plate-they gradually refine the surface of the object through multiple processes until it shows a mirror-like brightness.

Specifically, this process involves multiple variable factors such as speed settings, the amount of pressure applied, etc., which need to be carefully controlled to achieve good results. At present, the industry generally follows a strict evaluation standard system to measure whether the final result is qualified. In the long run, having high-quality polished plates can not only enhance the sense of product grade, but also win more market share for enterprises to establish a good brand image.

All-round protective measures: ensure the safety of every operation

Although the above three kinds of accessories have irreplaceable functions, there are still some risk factors that can not be ignored in practical applications. To this end, manufacturers have introduced a number of innovative safety precautions to minimize the chance of accidents. For example, the introduction of explosion-proof design concept to avoid accidental collision caused by spark explosion accident; the installation of intelligent sensors to monitor temperature changes in time to cut off the power supply to protect users from injury and so on.

In addition to hardware, software training is also critical. Enterprises should strengthen the basic knowledge education of employees to teach them to identify potential risk points and master the correct maintenance methods to make better use of existing resources to create greater value. At the same time, it is necessary to organize emergency drills regularly to improve the team cooperation ability and the ability to respond to emergencies.

From Getting Started to Mastery: The Advanced Path for DIY Enthusiasts

Nowadays, more and more home users are getting involved in small-scale renovation activities to solve problems by themselves, which can not only save money but also exercise their hands-on ability. Why not? But friends who are new to such projects may face a lot of confusion and don't know how to start.

In view of this situation, we have specially prepared a detailed teaching material covering all aspects from basic knowledge explanation to advanced skill sharing, hoping to provide practical help for the majority of fans. Here we will focus on several commonly used adjustment techniques, such as angle control points, how to reasonably distribute the force parts, etc., and let everyone understand and absorb relevant knowledge points more quickly through graphic forms.

The choice of professional technicians: the best helper to improve work efficiency

Professional engineers and technicians face heavy and pressing challenges every day. In this case, it is particularly important to choose a high-performance auxiliary tool. Through field visits to many large factories, it is found that almost all excellent enterprises will give priority to the configuration of angle grinders and related accessories with the above characteristics. Because this is not only to simplify the work process to improve the production rate is related to the core competitiveness of enterprises can be sustained development.

In fact, many senior practitioners have long been aware of this and incorporated it into the daily procurement plan to actively introduce advanced technology and equipment at home and abroad to continuously promote the industry to move forward. In the next few years, more revolutionary breakthroughs are expected to emerge to rewrite the existing pattern.