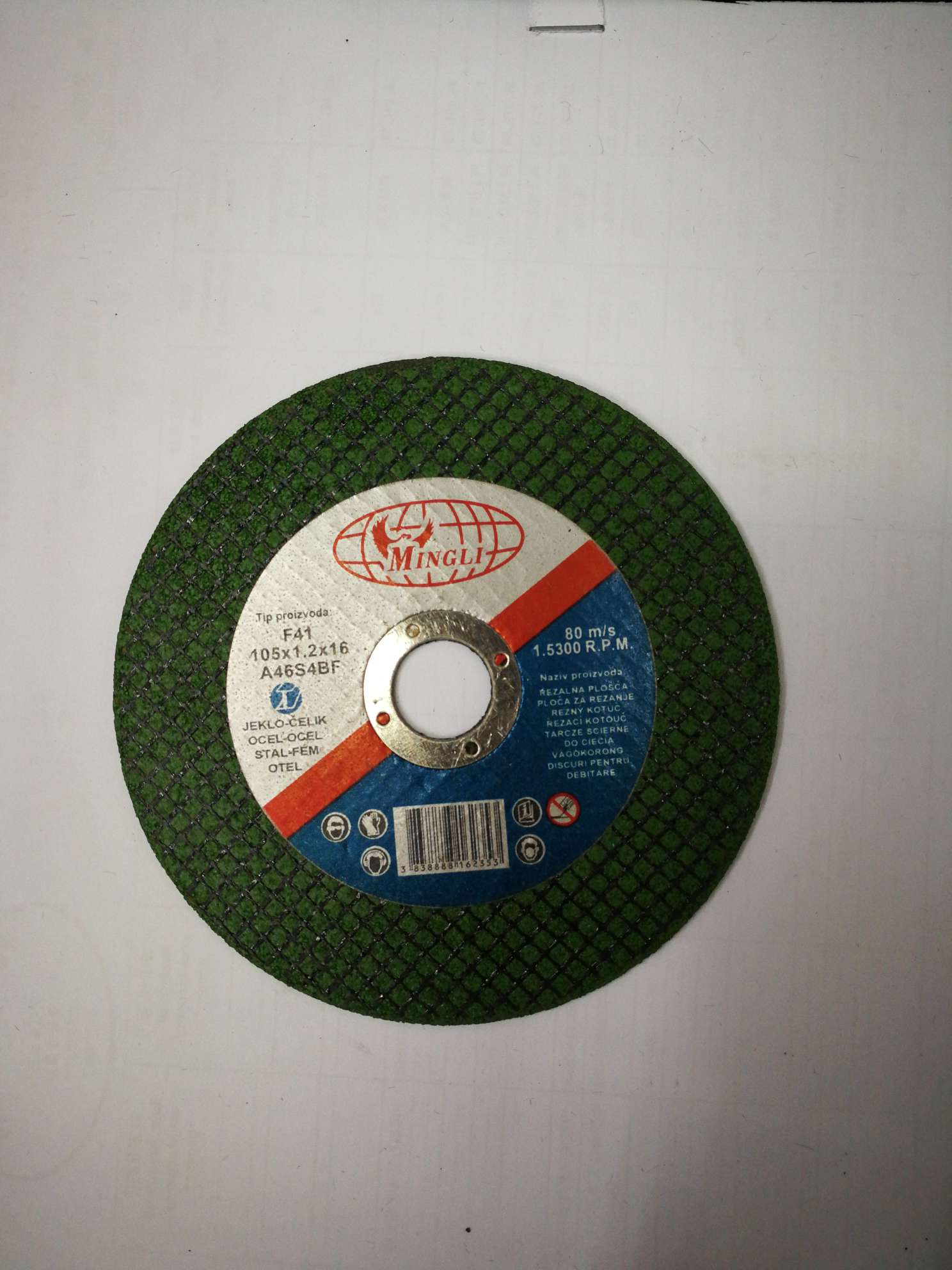

Understanding the MINGLI Eagle Ball Cutting Pieces is crucial for those seeking to enhance operational efficiencies in various industries. These cutting pieces are specifically designed to meet rigorous demands while ensuring high performance.

Comprehensive Overview of MINGLI Eagle Ball Cutting Pieces

The MINGLI Eagle Ball Cutting Pieces measure 105×1.2mm, optimized for precision cuts across a diverse range of materials. Made by Strong Abrasives Co., LTD, these cutting tools are affordable and reliable, combining advanced manufacturing techniques with robust material composition to deliver exceptional results.

Specifications and Dimensions

The specifications include a standard size of 105×1.2mm, which ensures versatility and compatibility with various industrial equipment. This dimension is precisely chosen to balance durability with cutting efficiency, making it an excellent choice for multiple applications.

Material Composition and Manufacturing Process

Constructed from high-grade abrasive materials, the MINGLI Eagle Ball Cutting Pieces undergo stringent quality control processes. The blend of ingredients ensures resistance to wear and tear, promoting longer lifespans even under intense use conditions.

Key Features that Enhance Performance

Precision Engineering for Accuracy

Each piece benefits from precision engineering, delivering accurate cuts without compromising on speed or reliability. This level of accuracy minimizes errors, thus enhancing overall productivity.

High Durability and Long Lifespan

Durability is a hallmark feature, backed by superior manufacturing processes that resist chipping and breakage. Customers can expect sustained performance over extended periods, reducing the frequency of replacements.

Resistance to Wear and Tear

The pieces exhibit exceptional resilience against abrasion and mechanical strain, maintaining their functional integrity through countless cycles of use.

Superior Cutting Efficiency

Engineered for high-performance cutting, these tools ensure swift material removal rates, saving valuable time in industrial operations.

Comparative Analysis with Competitors

Performance Metrics Comparison

Cutting Speed

Compared to competitors, the MINGLI Eagle Ball Cutting Pieces offer faster cutting speeds, which translates directly into enhanced throughput in manufacturing processes.

Longevity

Tests and user feedback suggest these pieces last significantly longer than many other market alternatives, offering greater value over time.

Cost-Efficiency

When considering both purchase price and lifespan, these cutting pieces represent a cost-effective solution suitable for budget-conscious operations.

User Reviews and Feedback

Satisfied users across different sectors commend the product's robustness, consistency, and economic sense. Reviews highlight the smooth integration into existing setups and noticeable improvements in output quality and project timelines.

Case Studies Showcasing Real-World Applications

Real-world cases reveal substantive enhancements in efficiency and product quality when companies switch to MINGLI Eagle Ball Cutting Pieces. Specific studies illustrate notable gains in heavy machinery fabrication, aerospace component production, and more.

Applications in Various Industries

MINGLI Eagle Ball Cutting Pieces find utility across several demanding sectors:

Heavy Machinery and Automotive Manufacturing

In automotive plants and heavy machinery assembly lines, these cutting pieces help achieve fine tolerances and smooth finishes, essential for meeting industry standards.

Aerospace and Defense Sectors

The precision and reliability of MINGLI Eagle Ball Cutting Pieces make them ideal for critical aerospace and defense applications where exactness is non-negotiable.

Construction and Metal Fabrication

Aiding in the fast-paced environment of construction sites and metal workshops, these tools facilitate quick yet precise cutting of steel beams, pipes, and sheet metal.

Electronics and Precision Equipment

For electronics and intricate machinery production, these pieces prove invaluable in executing highly detailed cuts without impacting delicate components.

Benefits for Industrial Operations

The advantages of deploying MINGLI Eagle Ball Cutting Pieces extend beyond mere functionality:

Increased Productivity and Workflow Efficiency

With their superior cutting speed and low downtime requirements, operations see considerable boosts in daily output and job completion rates.

Reduction in Downtime and Maintenance Costs

Long-lasting and hard-wearing, these pieces minimize interruptions due to tool changes and maintenance, driving down associated costs substantially.

Enhanced Safety Features for Operators

Designed with operator safety in mind, their stability and predictability reduce mishaps and ensure safe handling during intensive tasks.

Contribution to Overall Operational Excellence

Ultimately, incorporating these cutting tools fosters better end-to-end process management, leading to heightened satisfaction among clients and stakeholders alike.

Tips for Optimal Usage

Proper Installation and Setup

Ensuring correct installation and setup is vital for optimizing tool performance. Precise alignment during mounting will lead to smoother operation and reduced wear.

Maintenance Routines to Extend Lifespan

Regular cleaning and inspection prevent premature degradation, extending the working life of each piece.

Best Practices for Achieving Maximum Performance

Implement consistent best practices like using appropriate cutting speeds and pressures to maximize efficiency and prolong tool usability.

Safety Precautions and Guidelines

Adhering strictly to safety guidelines reduces risk factors for operators, thereby securing a safer working environment.

Testimonials and Success Stories

Interviews with Industry Professionals: Senior engineers and shop managers express profound satisfaction with how MINGLI Eagle Ball Cutting Pieces have transformed their workflows.

Success Stories from Satisfied Clients: Firms report substantial improvements in task execution times and cut quality after integrating these cutting pieces into their operations.

Quantitative Success Metrics from Real-World Usage: Concrete metrics such as a 20% reduction in finishing times and a 15% increase in tool longevity underline the tangible benefits realized by customers.

Future Innovations and Developments

The landscape of cutting technology continues to evolve, with promising developments awaiting implementation:

Upcoming Advancements in Cutting Technology

Expect breakthroughs in material sciences and engineering methods that will further elevate the cutting efficacy and lifespan of these tools.

Potential Upgrades to MINGLI Eagle Ball Cutting Pieces

Ongoing research focuses on refining design and material properties, aiming at producing an even more proficient next-generation product line.

Industry Trends and Future Outlook

The progressive shift towards automation and precision underscores the significance of investing in superior cutting instruments like the MINGLI Eagle Ball Cutting Pieces.

In conclusion, MINGLI Eagle Ball Cutting Pieces 105×1.2 emerge as indispensable elements within numerous industrial frameworks. Their engineered sturdiness, superb cutting abilities, and cost-effectiveness equip businesses with the necessary tools to excel in competitive arenas. Through continuous innovation and application adaptability, these cutting pieces stand poised to remain at the crest of industrial performance enhancement.