In the ever-evolving manufacturing sector, the choice of tools often determines the success or failure of a project. Today, we are focusing on a unique professional-grade angle grinder accessory suit, which combines ultra-thin cutting plates, grinding wheel plates and polishing plates to meet the needs of various industrial levels of grinding and polishing. Let's explore together how to open a new chapter of process innovation through this innovative combination.

Material Science Leap: Abrasion Resistance and Long-lasting Performance

It all starts with the basics-the materials you choose. This set of accessory suit uses high-strength wear-resistant materials, which can withstand extreme working conditions while ensuring long life and low maintenance costs. Whether it's cemented carbide or ceramic composites, each option is focused on achieving the perfect balance between optimal performance and safety. This is not only a tribute to science and technology, but also a adherence to the spirit of craftsmen.

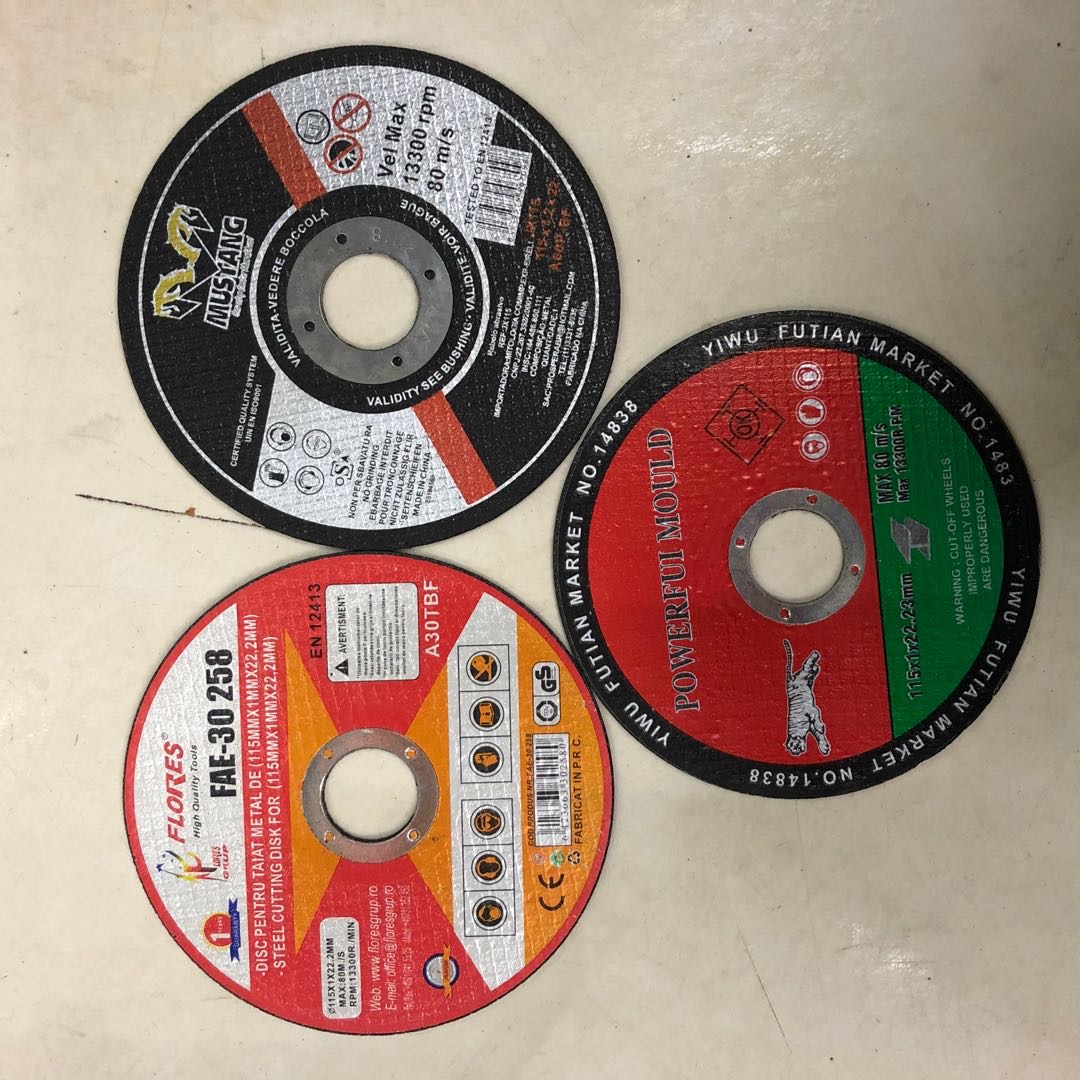

Figure 1: Performance of high-strength wear-resistant materials in practical applications, witnessing the power of technological innovation

Performance advantage: double guarantee of accuracy and efficiency

Under the high-speed rotation of the angle grinder, every cutting plate, grinding plate and polishing plate needs to show impeccable stability and accuracy. Thanks to the precise manufacturing process, this set of accessory suit can maintain extremely high machining accuracy under high-intensity use environments, whether it is quick removal of rough surfaces or meticulous surface treatment. This is a proof of the ultimate pursuit of craftsmanship and an interpretation of professionalism.

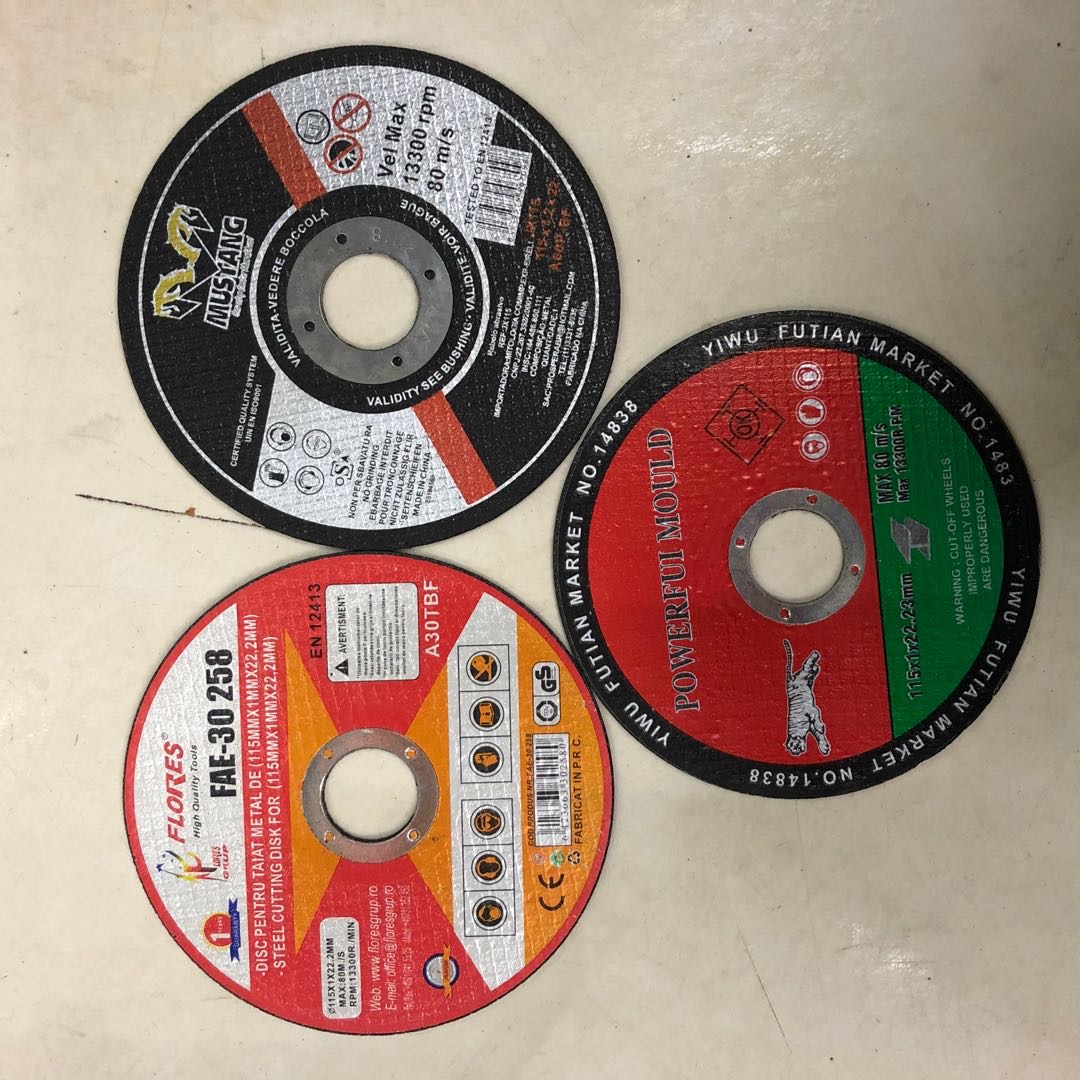

Figure 2: Excellent performance of professional-grade angle grinder accessory suit in different application scenarios, demonstrating its excellent performance

craftsman spirit: from design to quality of finished products adhere to

Every detail carries the wisdom and sweat of the craftsman. From the initial drawing design, to the mold production, to the final product inspection, every link strictly follows the international quality standards to ensure that every user gets the fine products that have been tempered. This kind of almost demanding attitude towards quality is the key to winning the trust of the market. Behind each product, there are countless days and nights of hard work, only for that part of the unremitting pursuit of perfection.

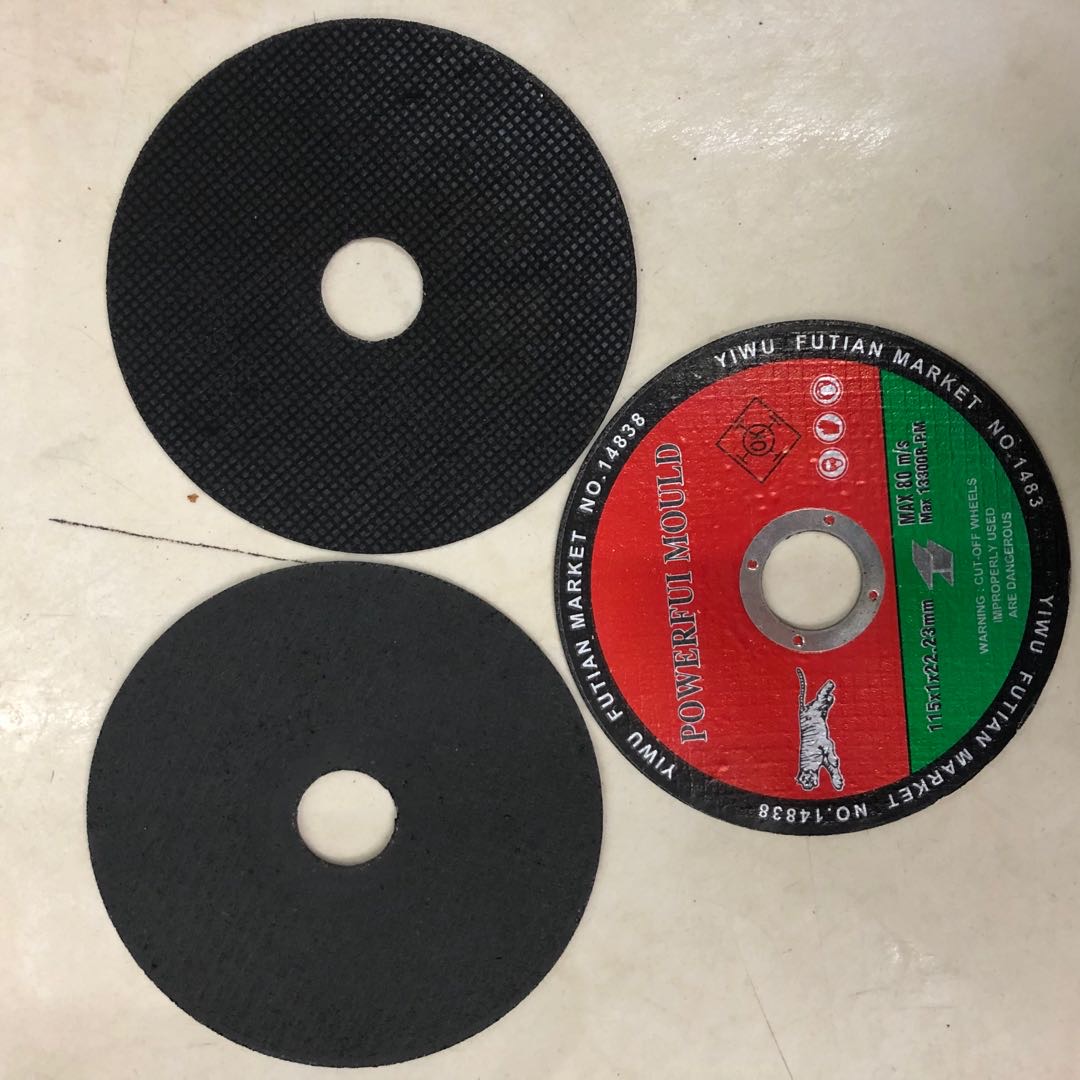

Figure 3: Fine manufacturing process of professional-grade angle grinder accessory suit, showing the spirit of ingenuity and excellence

Application Model: Outstanding Contribution Across Fields

Whether it's a metalworking workshop, a construction site, or the shipbuilding industry, this professional-grade angle grinder accessory suit can be found everywhere. It can not only easily deal with steel, concrete, ceramic tiles and other hard materials cutting and grinding, but also in wood, plastic and other soft materials play excellent performance. The combination of flexibility and versatility makes it a right-hand man in the hands of many industry professionals, bringing them endless work convenience and efficiency improvement. Behind every successful application is the result of a deep understanding of technological innovation and market demand.

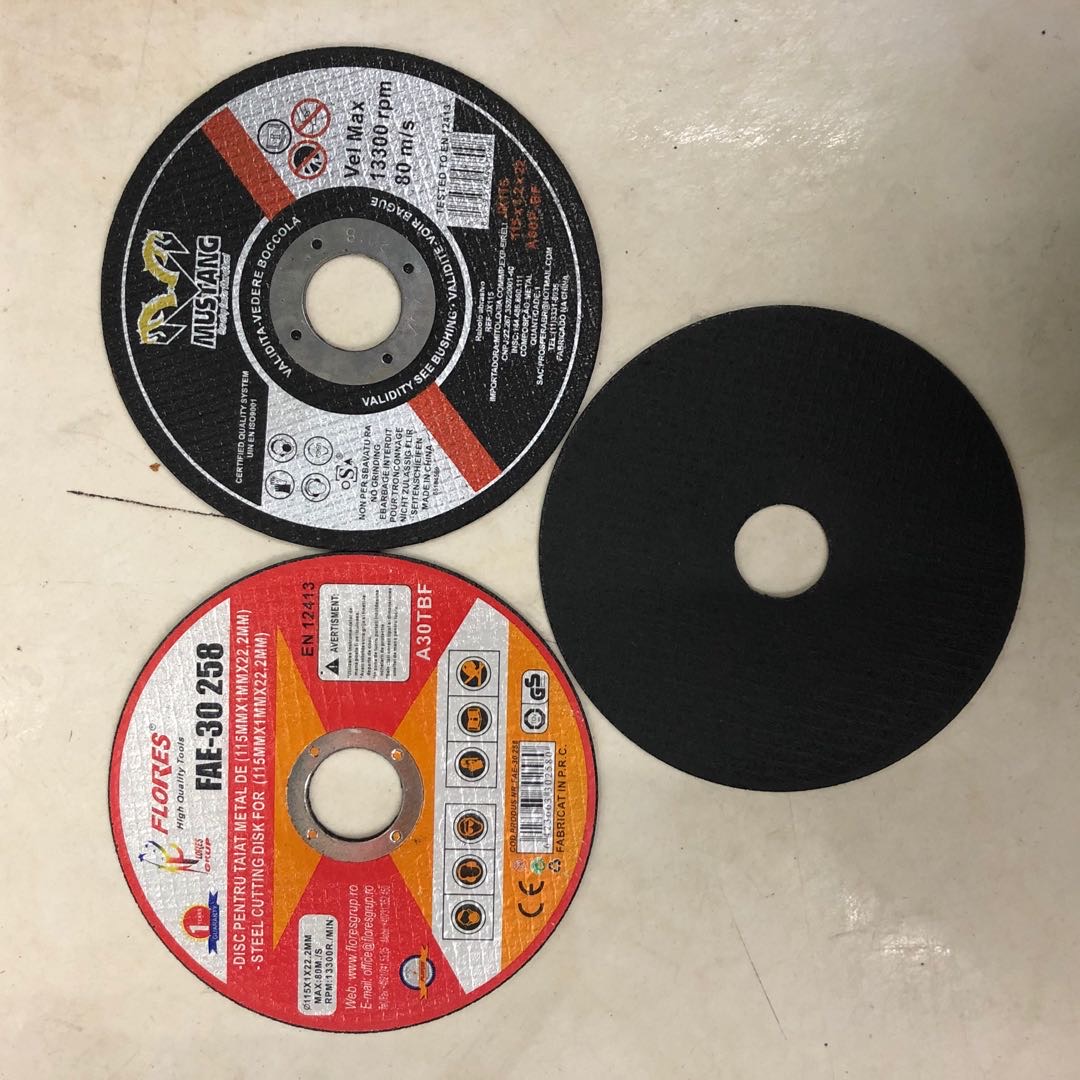

Figure 4: The wide range of application cases of professional-grade angle grinder attachment suit in real working environments, witnessing their practical value and influence