For professionals engaged in metal processing or stone finishing, a high-performance angle grinder is undoubtedly the most effective good helper. However, only a high quality accessory can truly unlock its potential. Today we will focus on the three key components of ultra-thin cutting plate, grinding wheel plate and polishing plate, taking you to understand their unique charm and specific application scenarios.

From efficiency to precision: why it is important to choose high-quality angle grinder accessories

High-quality angle grinder accessories can not only greatly improve work efficiency, but also ensure that every step of the operation is accurate and in place. Whether in the face of hard steel or brittle marble, the right tool can always make the work more effective. Therefore, in the purchase process must pay attention to the wear resistance and stability of the product.

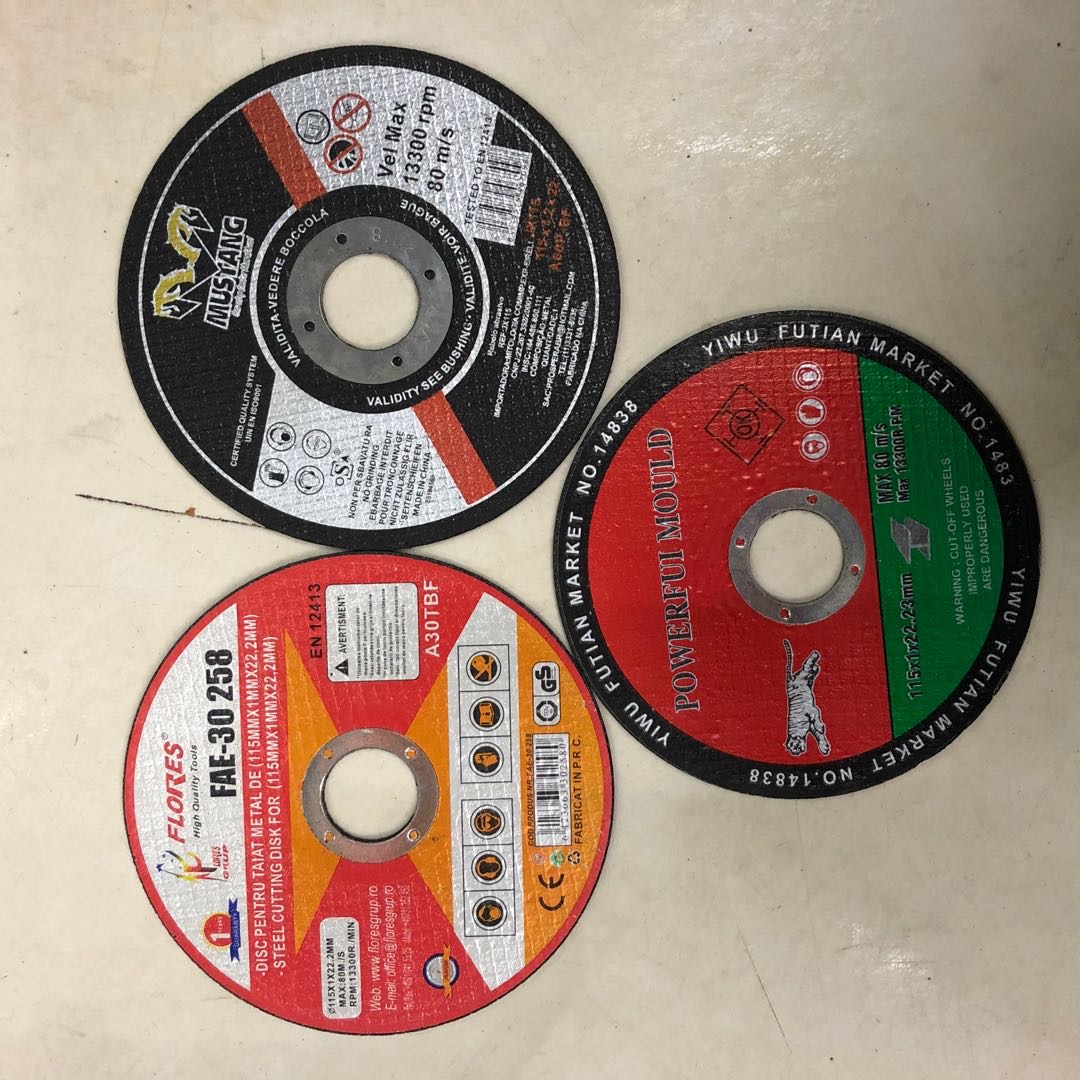

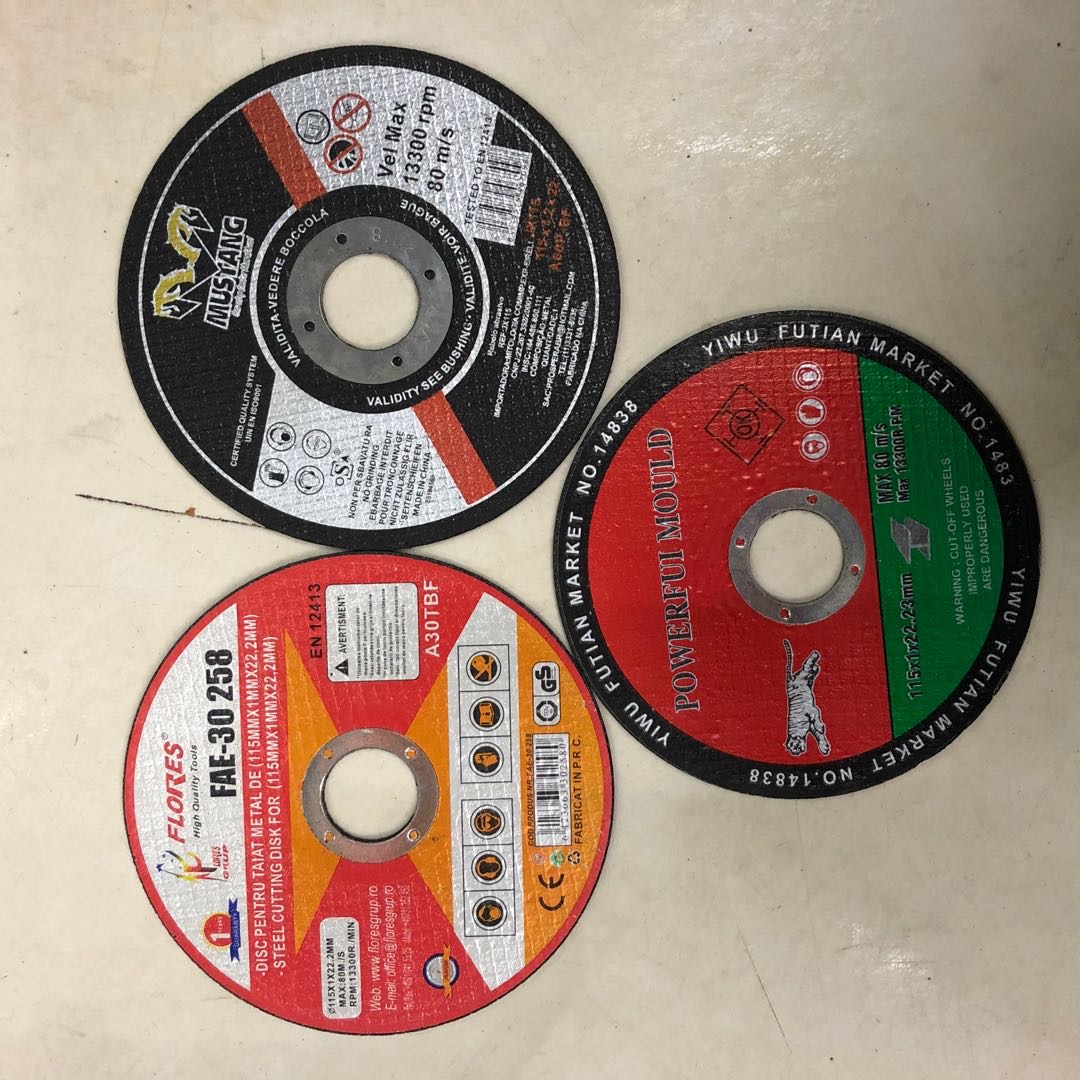

In-depth analysis: the unique advantages and application scope of ultra-thin cutting board

Our ultra-thin cutting board is known for its slim design, which can perform precise cutting tasks in tight spaces without damaging the surrounding materials. Its sharp edges have been specially treated with durable characteristics, even if the continuous high-intensity operation can maintain good condition.

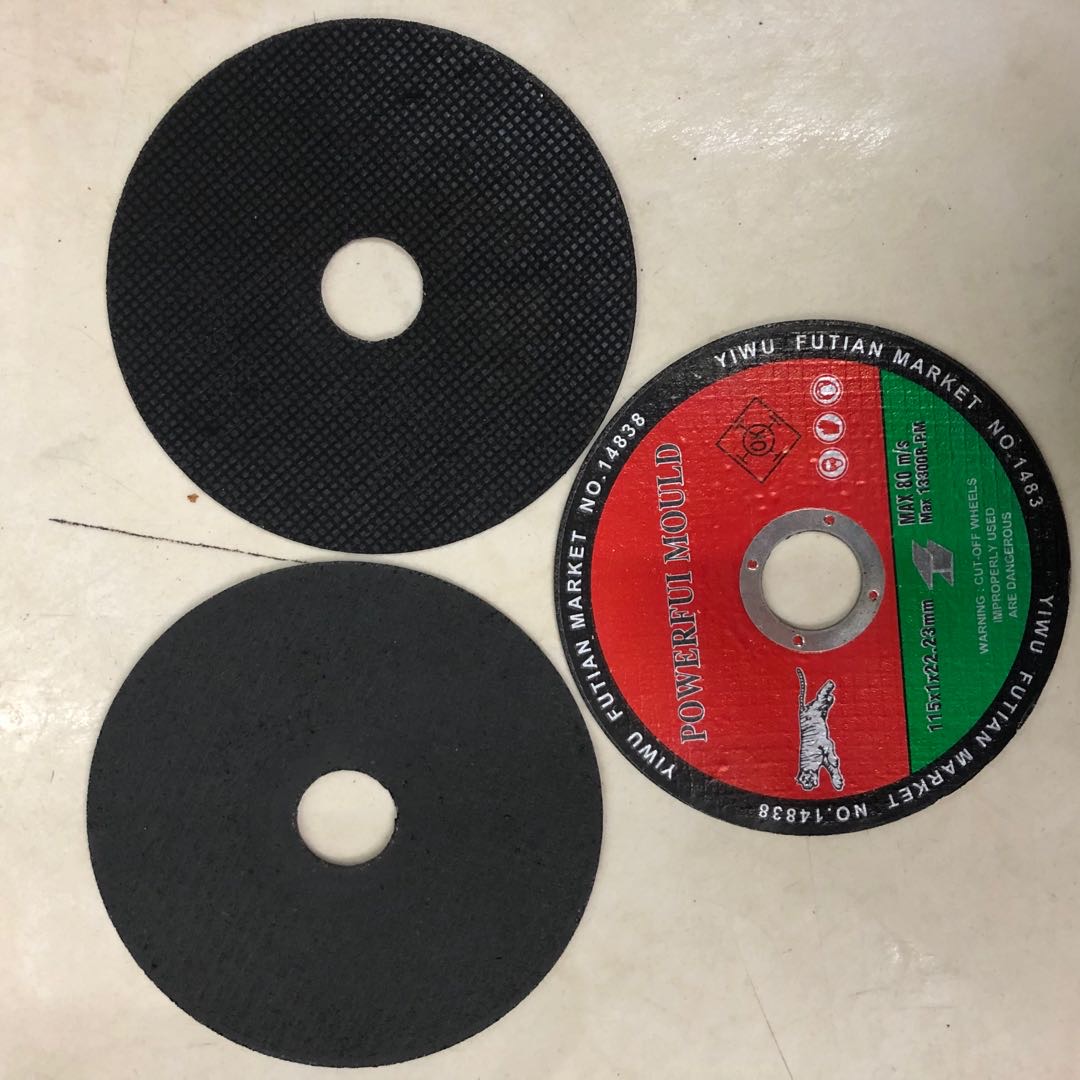

The secret weapon of grinding: the working principle and various functions of the grinding wheel plate

If the cutting is about speed, then the smooth surface depends on the efficient grinding wheel technology. This product is made of advanced composite materials, and the strength can be adjusted according to different roughness to meet the needs of various materials-from rough deburring to fine contour modification.

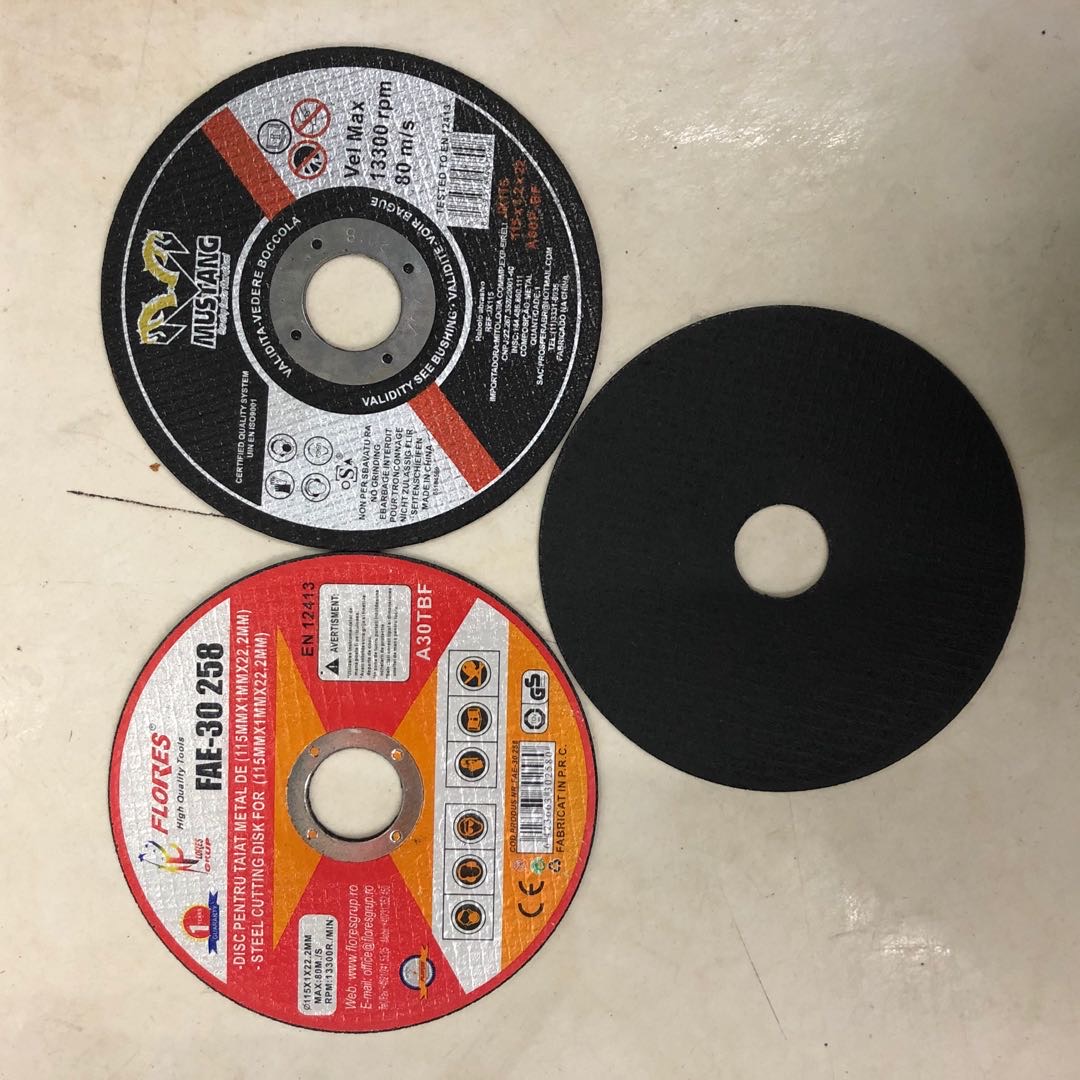

The art of surface treatment: how to achieve a smooth and delicate effect with polished plates

When all the preliminary steps are completed, the final stage is the final retouching stage. At this point, it is necessary to use a special type of polishing disc under the covering layer of soft and evenly distributed granular material to carry out the final process. It can effectively eliminate any residual traces and restore the surface of the object to a mirror-like shiny appearance.

Scene measurement: recommendations for optimal configuration of different types of workpieces

It is particularly important to arrange the corresponding specifications and models reasonably according to the requirements of different projects. For example, in the secondary processing of aluminum alloy products can give priority to the thicker style of grinding head; and for the tile gap cleaning, the lightweight version is obviously more flexible, convenient and easy to control.

Safety first: the key points for the correct use of angle grinder accessories

no matter how excellent the equipment is, if it does not follow the standard instruction manual, there will still be potential safety hazards, risks, and the probability of potential problems will increase many times. oh, friends, remember to wear a full set of protective equipment and confirm that the installation is firm before turning on the machine!

Economical and efficient: tips to extend the service life of blades

in order to further save costs and maximize the use of resources, please be sure to form the habit of regular cleaning and maintenance and avoid continuous operation under extreme load for a long time. this can greatly delay the wear process and thus increase the overall life span length. oh, dear friends ~

in summary, A complete set of angle grinder components should include the above-mentioned functional components to meet the diversified actual needs. It is the king's way to switch modes quickly and cope freely when the situation arises, isn't it?