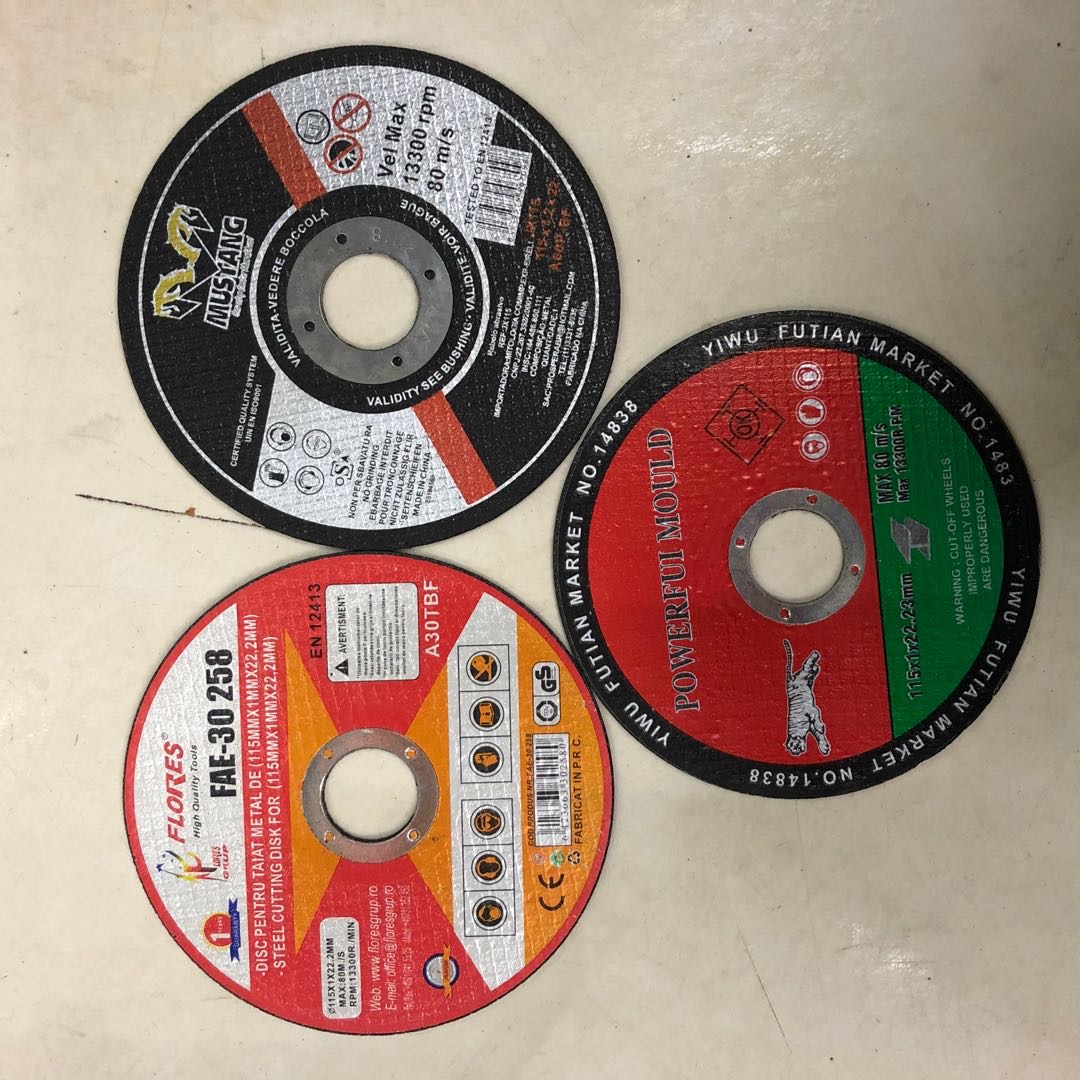

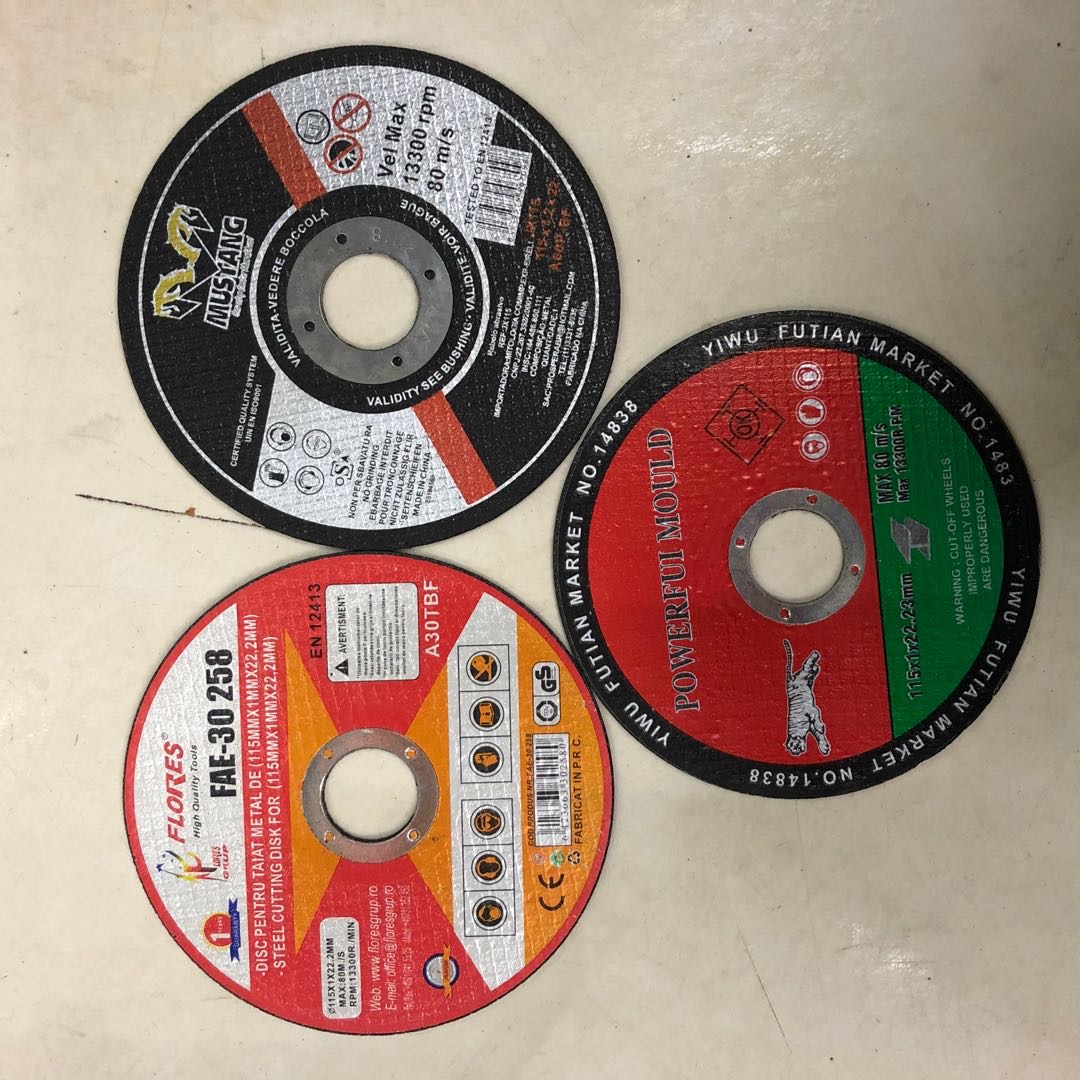

In modern industrial manufacturing, angle grinder accessories have become an indispensable and important helper for craftsmen. Whether it is metal processing or stone finishing, high-quality cutting and polishing accessories can significantly improve the accuracy and efficiency of the work. Today, we will delve into two highly respected products-ultra-thin cutting plates for angle grinders and multi-function grinding wheel polishing plates.

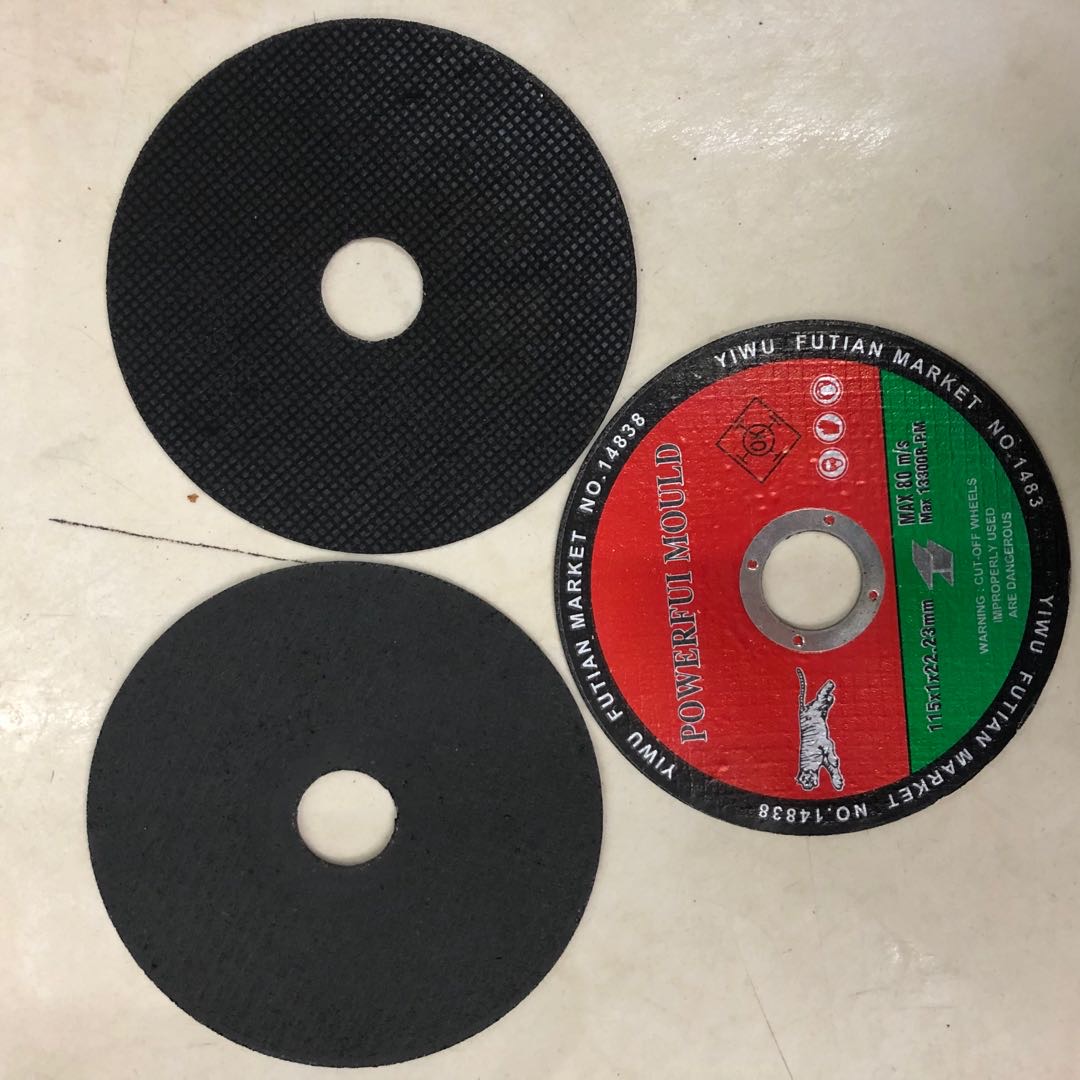

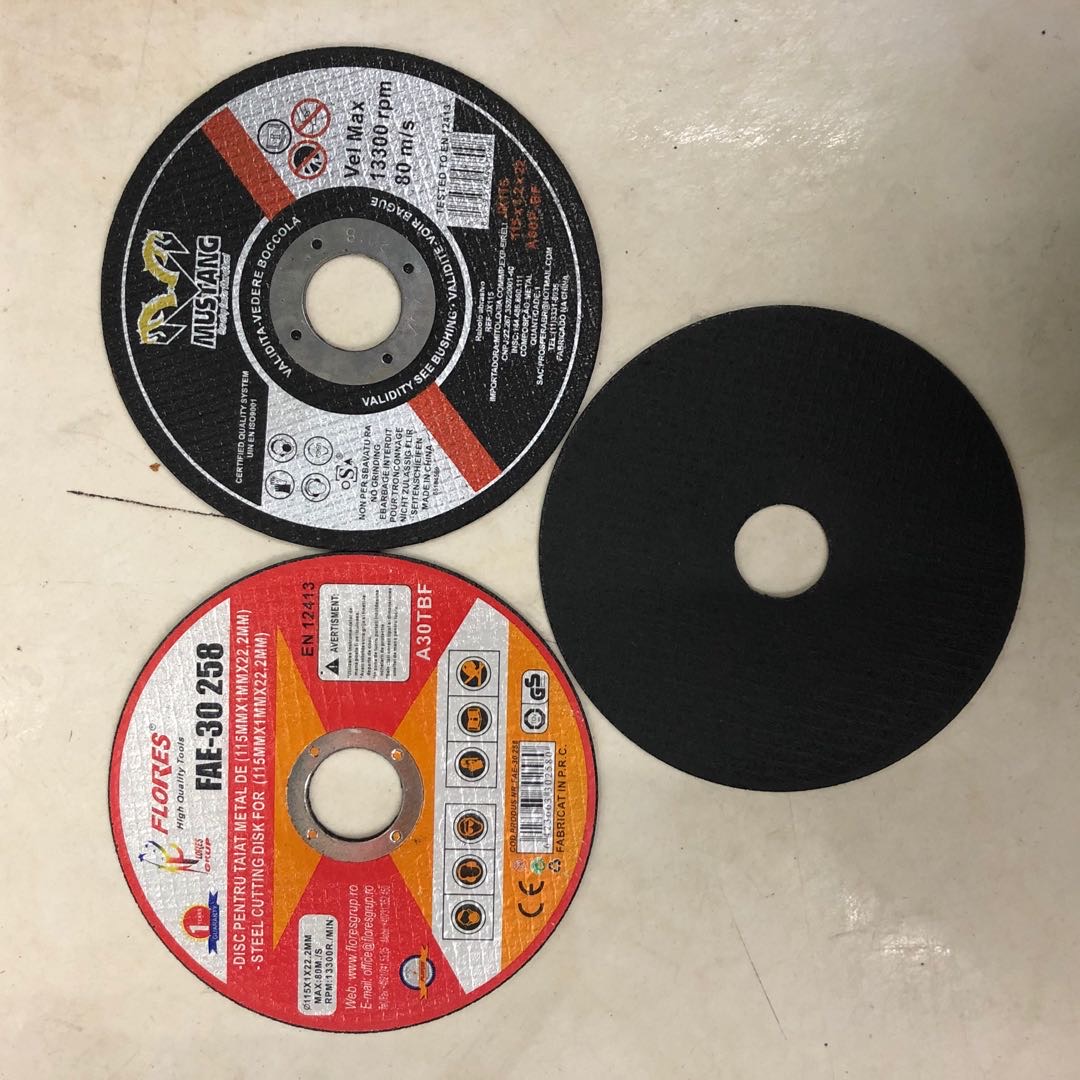

Ultra-thin cutting boards are known in the industry for their outstanding precision. Crafted from advanced materials, this cutting board enables clean cuts on a variety of hard surfaces while reducing the risk of splashing debris. This is especially important for professionals looking for perfect details. In addition, its lightweight design also greatly reduces the fatigue of long-term use.

And another star product, the multi-purpose grinding wheel polishing board, shows the ability to change from a rough surface to a mirror gloss. It is suitable for a variety of materials, including stainless steel, aluminum alloy and even marble and other high-end building materials. With a unique particle formulation, this polishing plate can be quickly polished to the desired effect without damaging the substrate.

These two accessories are widely used in many fields such as construction, automobile maintenance and home decoration. For example, during the installation of kitchen countertops, ultra-thin cutting boards can help workers accurately cut quartz stone plates; while in the body repair process, multi-function grinding wheels can quickly eliminate dents and restore paint brilliance.

It is worth noting that although these tools are powerful, they still need to follow basic safety regulations when using them to protect their health. Wearing protective glasses to prevent dust from entering the eyes and ensuring that the machine is firmly connected before starting the operation are key steps that cannot be ignored.

When it comes to the differences between ultra-thin cutting boards and other traditional models, the former undoubtedly shows obvious technical advantages. Unlike heavy traditional discs, which are prone to stuck, the new model is easier to cut into complex corner areas to complete detailed tasks with slender edges.

There are also several suggestions for consumers on how to choose the specific configuration that suits their needs. First of all, it is necessary to clarify which type of material (e. g. steel vs glass) the plan mainly deals with, and then select the ideal option for the adaptation of the corresponding specification parameters according to the budget range.

A lot of user feedback shows that they are extremely satisfied with these two products. "Since the switch to the new ultra-thin cutting board, the work efficiency has increased by at least 30%!" A senior carpenter so commented. There are many similar positive sounds, which fully proves that the product quality is trustworthy.

To maximize the value of your investment, routine maintenance is equally important. It is a simple but effective measure to clean up the residue regularly so as not to block the air holes and cause excessive heat to damage the equipment components. In addition, the storage environment should be dry and ventilated to prevent rust and corrosion to extend the service life.

With the continuous progress of science and technology, the research and development of new materials will continue to promote the innovation in the field of angle grinder accessories. It is expected that more new products with intelligent features will come out in the near future to further simplify the cumbersome process flow.