For many handicraft enthusiasts or professional construction personnel, angle grinder has become an indispensable weapon in daily work. However, it is far from enough to have an angle grinder. Only by choosing the right core accessories can we really realize its potential.

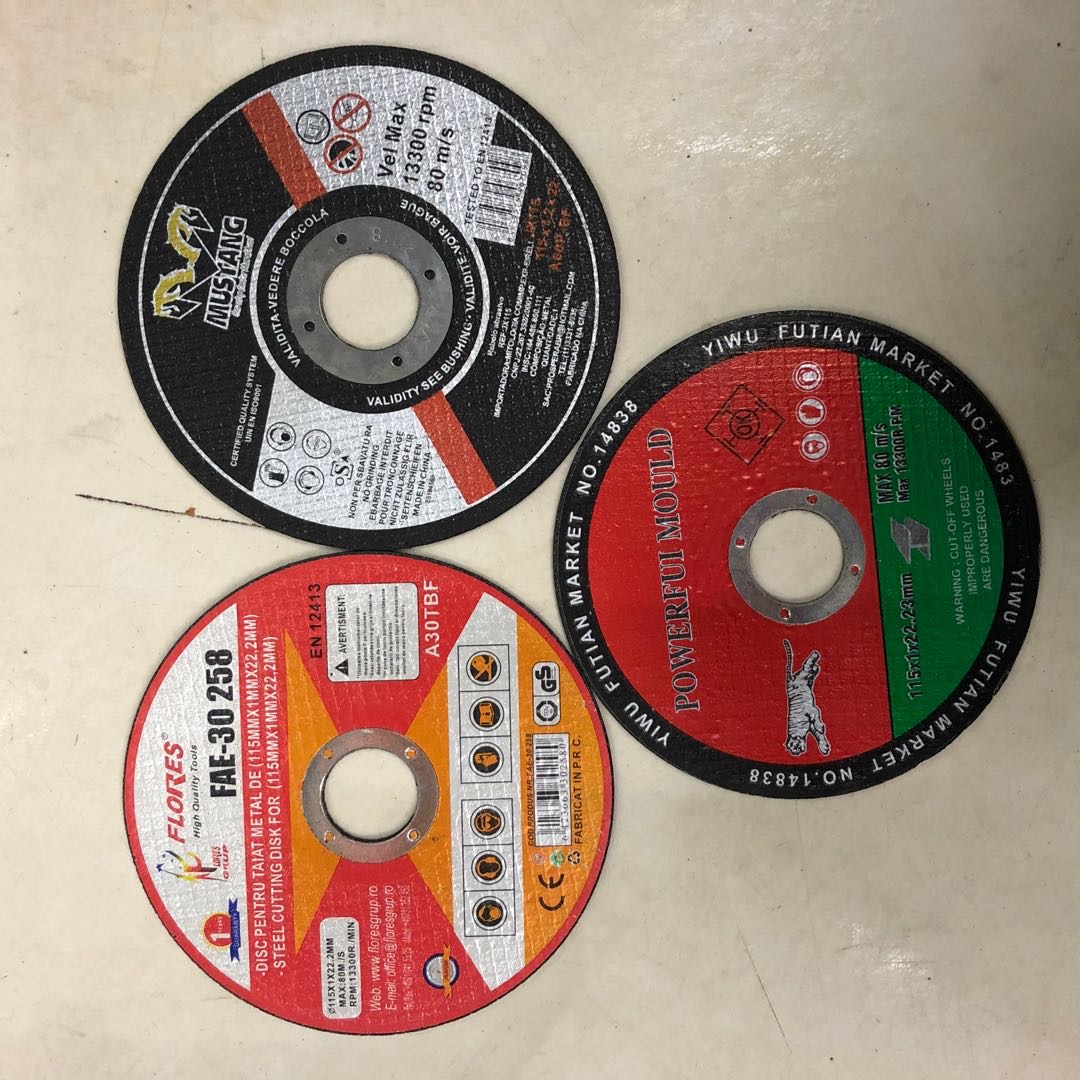

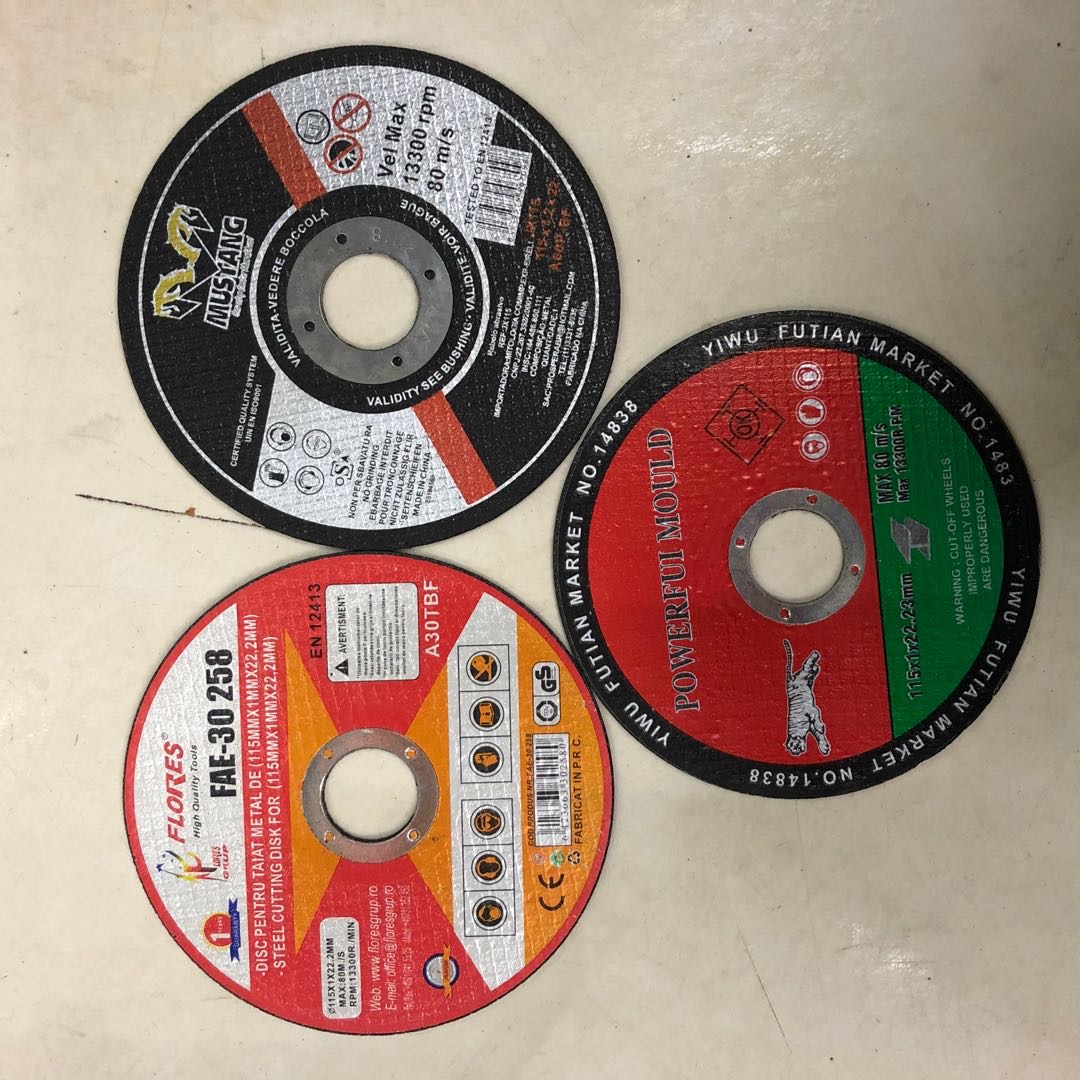

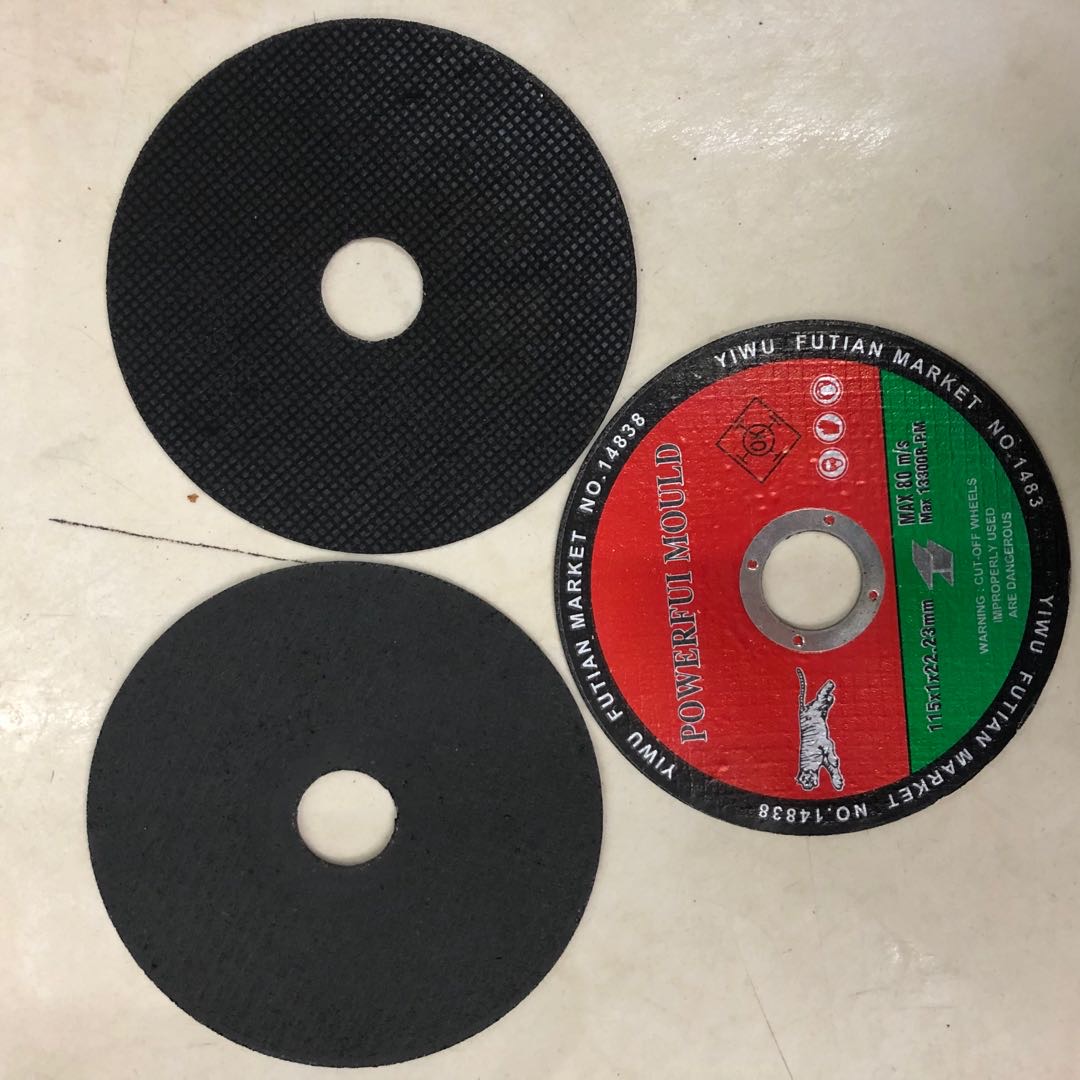

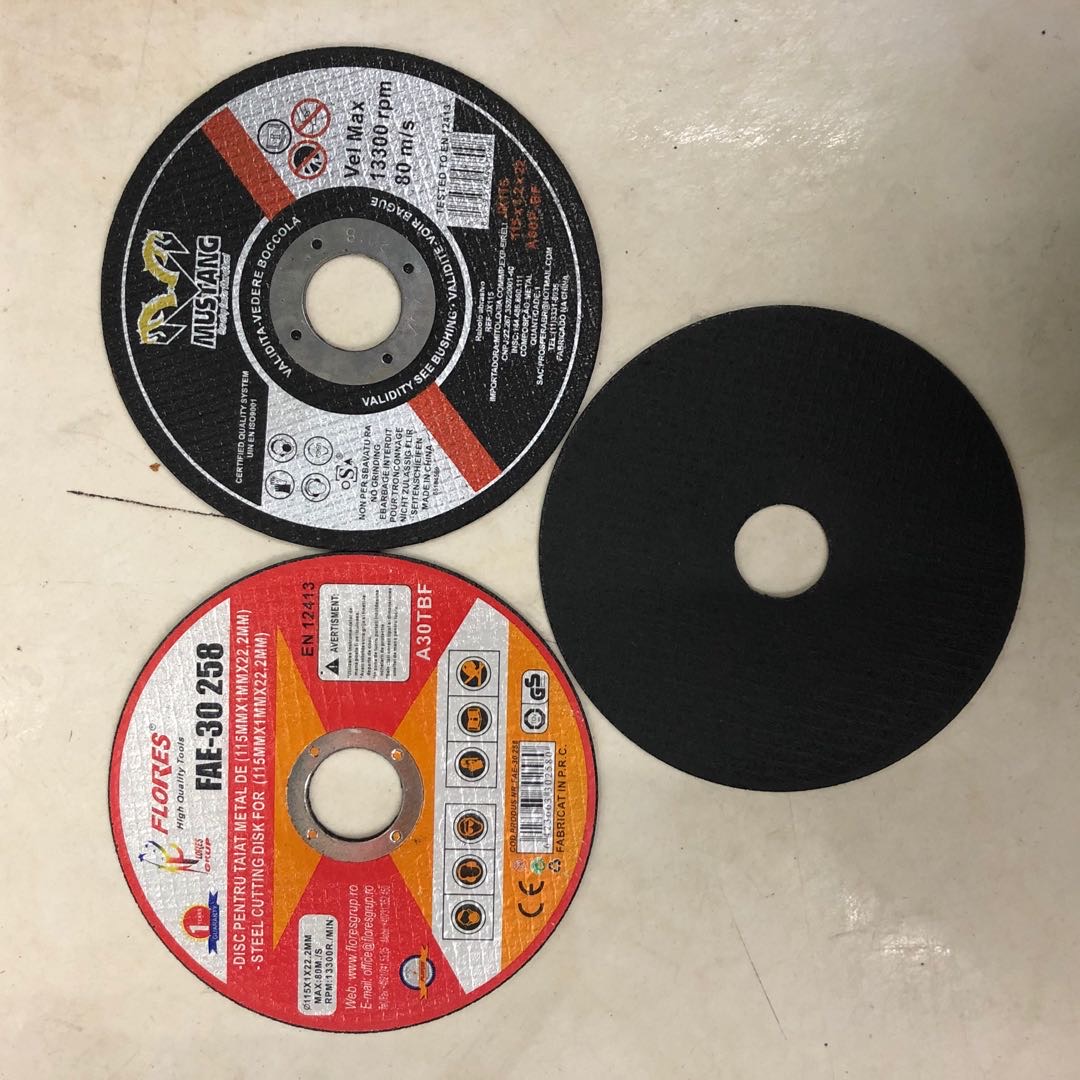

First, let's take a look at the highly respected ultra-thin cutting board. These products are known for their lightness and efficiency, enabling precise and rapid cutting operations on metal pipes or other hard substances. Due to the small thickness, the heat generated is relatively low, which greatly reduces the risk of deformation due to overheating; at the same time, it can effectively protect the surface of the processed object from unnecessary damage.

In addition to cutting tasks, you can choose a grinding wheel plate with excellent performance to complete the job when facing the needs of grinding. The modern market offers a wide range of grinding wheels, ranging from small diameters for fine edge dressing to large sizes for rough deburring over large areas. No matter what material you encounter (such as stone, wood or aluminum alloy), there is always a professional grinding wheel made of a specific formula can meet the challenge.

When pursuing the ultimate smooth texture, you can't miss the efficient polishing board option. They are combined with a soft base material through a special coating technology to give the object a bright and shiny appearance while retaining the original shape and contour. In particular, it is worth mentioning that the special series launched in the field of stainless steel products can not only make kitchen appliances look new, but also widely used in many industries such as auto parts renovation.

So how to judge a good plate? Here need to pay attention to two main dimensions-the quality of the material itself and the level of technology used in the manufacturing process. Generally speaking, raw materials with uniform density distribution and moderate hardness are more likely to form stable and durable finished products; in addition, components treated by advanced processes such as high temperature sintering tend to have stronger wear resistance and impact resistance.

Next, share some practical experience for reference. For example, in the home improvement project may involve ceramic tile opening work, then choose the wet water cooling type with diamond particle layer covering design is the most ideal; For the mechanical maintenance workshop, it is recommend to reserve a variety of specifications and models to flexibly deal with various emergencies.

Finally, don't forget that the correct maintenance method can significantly extend the actual life of these wearing parts! It is recommended to clean up the residual debris in time after each use to prevent blockage from affecting the normal operation efficiency next time, and properly store it in a dry and ventilated environment to avoid corrosion damage caused by humid environment.