Whether in the field of metal processing or stone dressing, a high-quality grinding wheel is always a key element to ensure high efficiency and precise work. Choosing a grinding wheel with superior performance can significantly reduce working time and improve the quality of the finished product.

Mastering the core: the impact of high-quality grinding wheel discs on operational efficiency

In modern industrial production, time and cost control is particularly important. The quality of the grinding wheel directly affects the performance of the angle grinder. For example, the use of high-performance ultra-thin cutting plates can greatly reduce the possibility of thermal deformation, so as to ensure accurate cutting and extend the life of the equipment. In addition, the high quality polished plate can make the surface more smooth and delicate, to meet the high standards of customer demand.

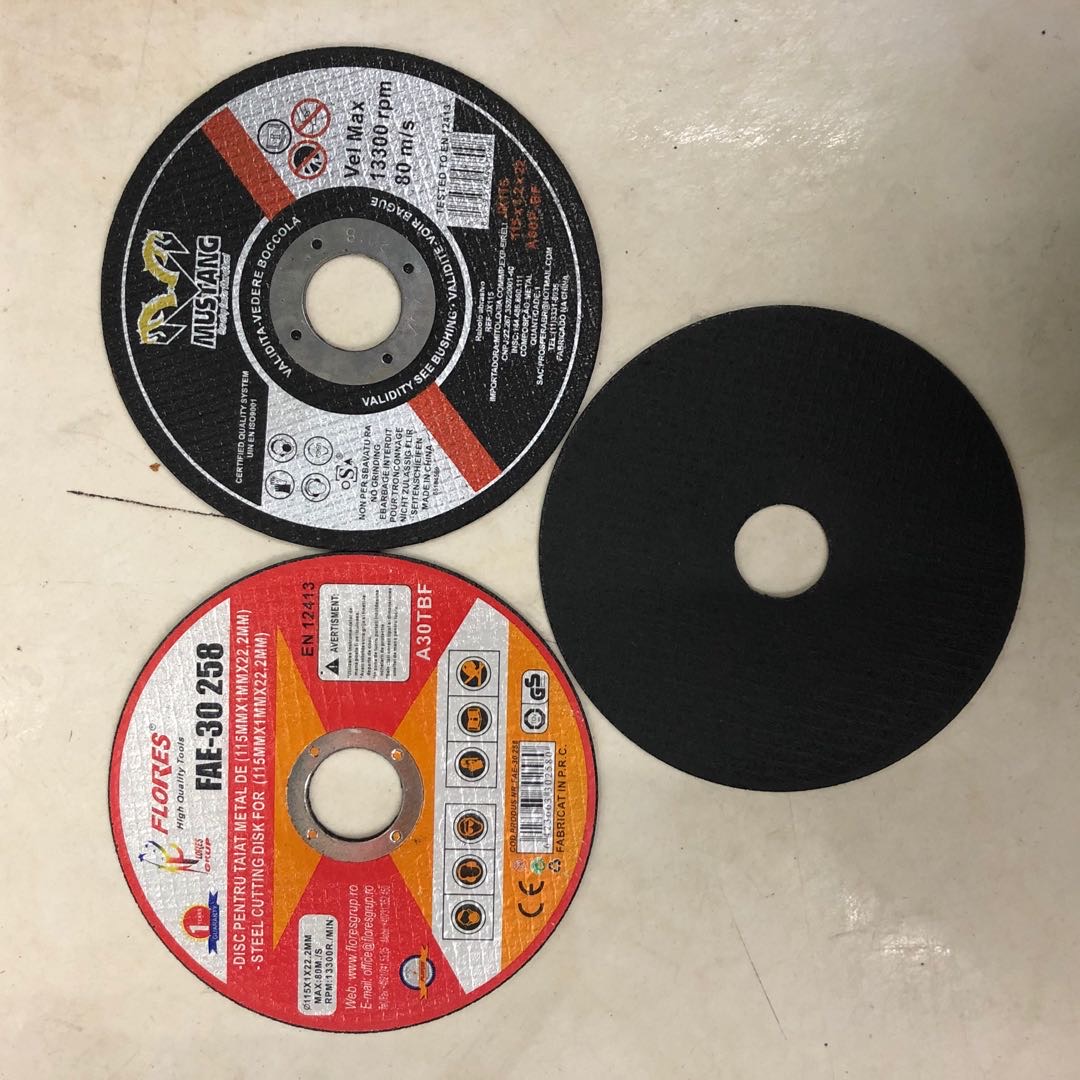

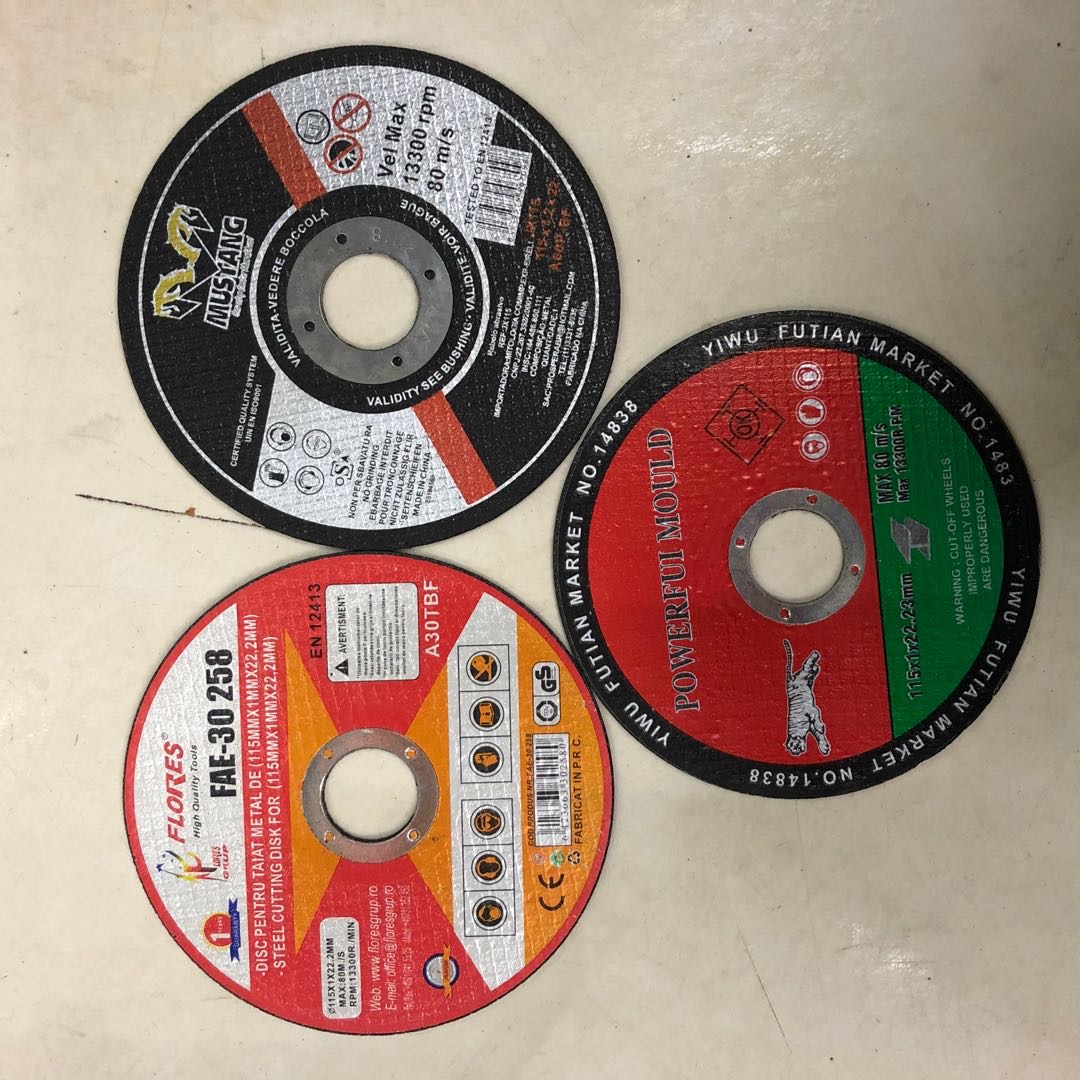

Comprehensive Analysis: Technical Characteristics and Scope of Application of Ultra-thin Cutting Board

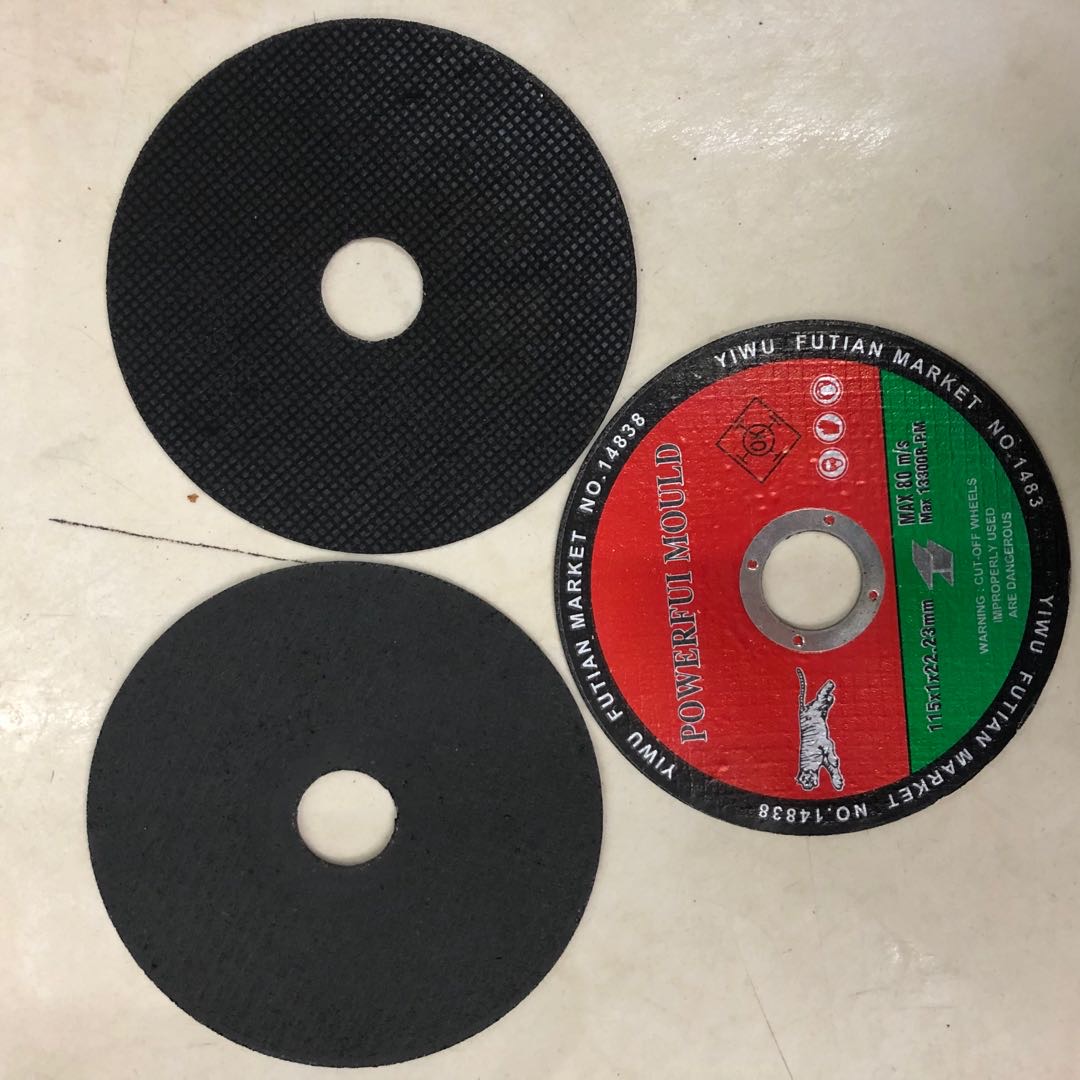

The ultra-thin cutting board is known for its extremely low height difference, which makes it particularly suitable for tasks that require a high degree of precision, such as cutting fine metal parts or engraving complex stone textures. Its main technical parameters include thickness, hardness and wear resistance. The thinner design reduces material waste, while the higher stiffness means greater resistance to tearing, which is especially valuable for high-intensity work tasks.

Perfect Polishing: How Polished Pad Helps You Achieve Superior Surface Treatment

The choice of the polishing plate depends on the desired final effect and the nature of the material to be treated. Polishing plates with different degrees of hardness and particle size will bring very different tactile and viewing experiences. For the more rough metal surface, you can choose a larger particle size model to quickly remove the excess part; and for the need for mirror-like gloss marble, it is more suitable to use a more soft and delicate polishing program.

Shopping tips: tips for choosing the right grinding wheel

With the variety of products on the market, it's important to make informed decisions. The primary consideration is the specific use-is the pursuit of extreme sharpness or even leveling? The second is budget constraints, and seeking the most cost-effective option within a reasonable range is often twice the result with half the effort. Finally, factors such as brand reputation and service guarantee cannot be ignored, because they are directly related to the quality of follow-up maintenance and support services.