Revealing the unique structure of the ultra-thin cutting board and the technological principles behind it

Modern industry is increasingly demanding tools, and our ultra-thin cutting board is a revolutionary product that came into being in this context. By using advanced high-strength ceramic composite materials, this grinding wheel plate not only achieves a breakthrough in thickness, but also combines excellent hardness and toughness. This unique construction makes it easy to face hard metals or other difficult materials.

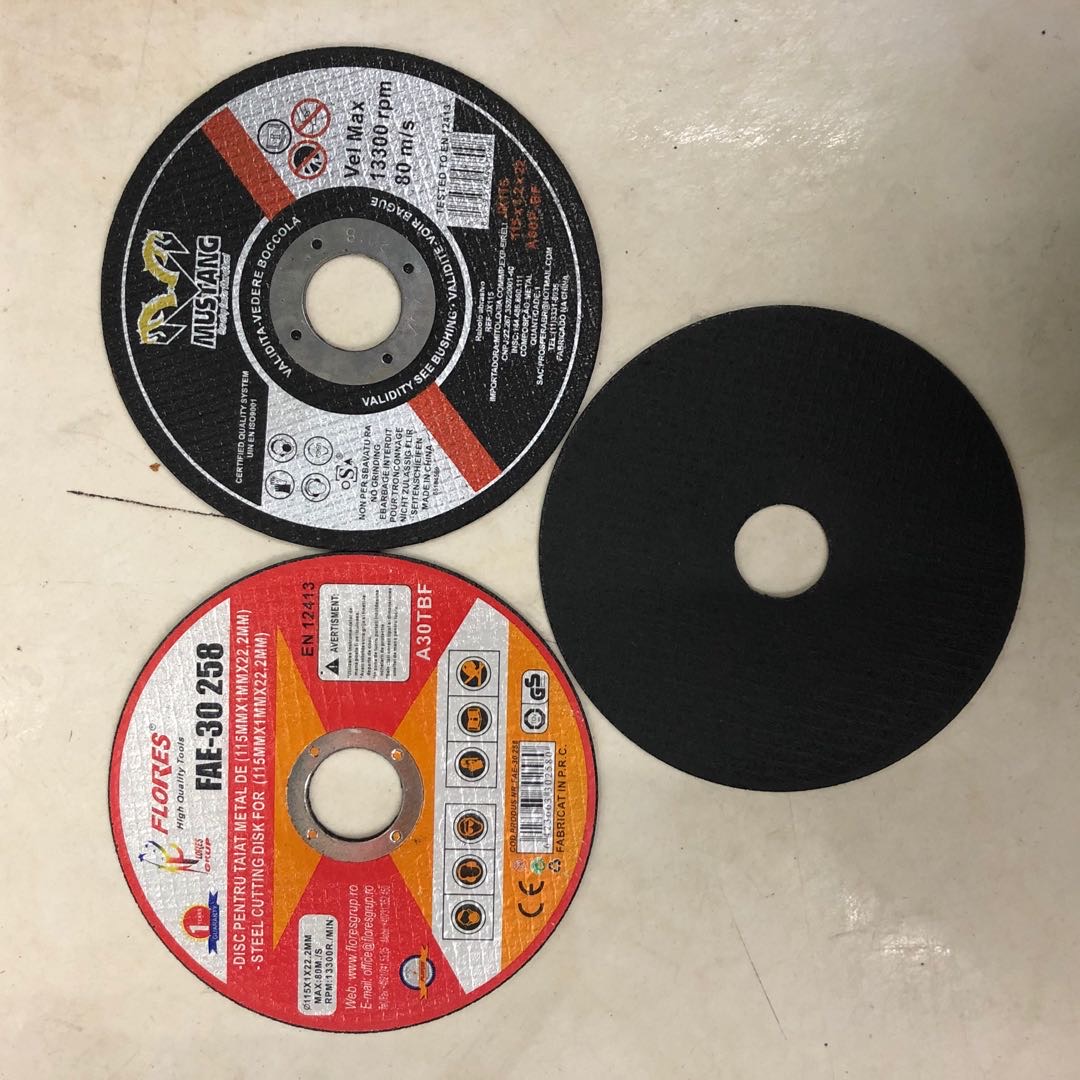

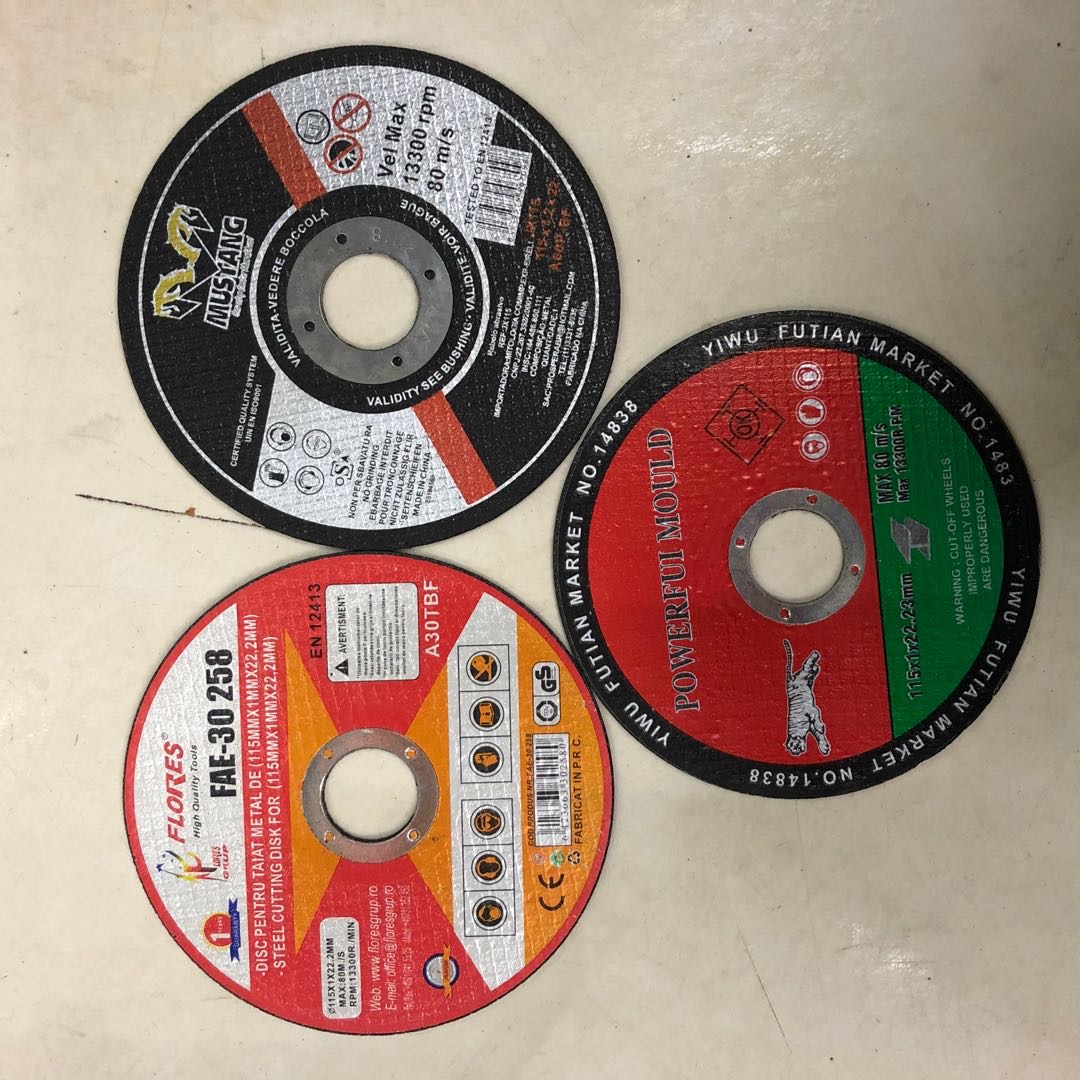

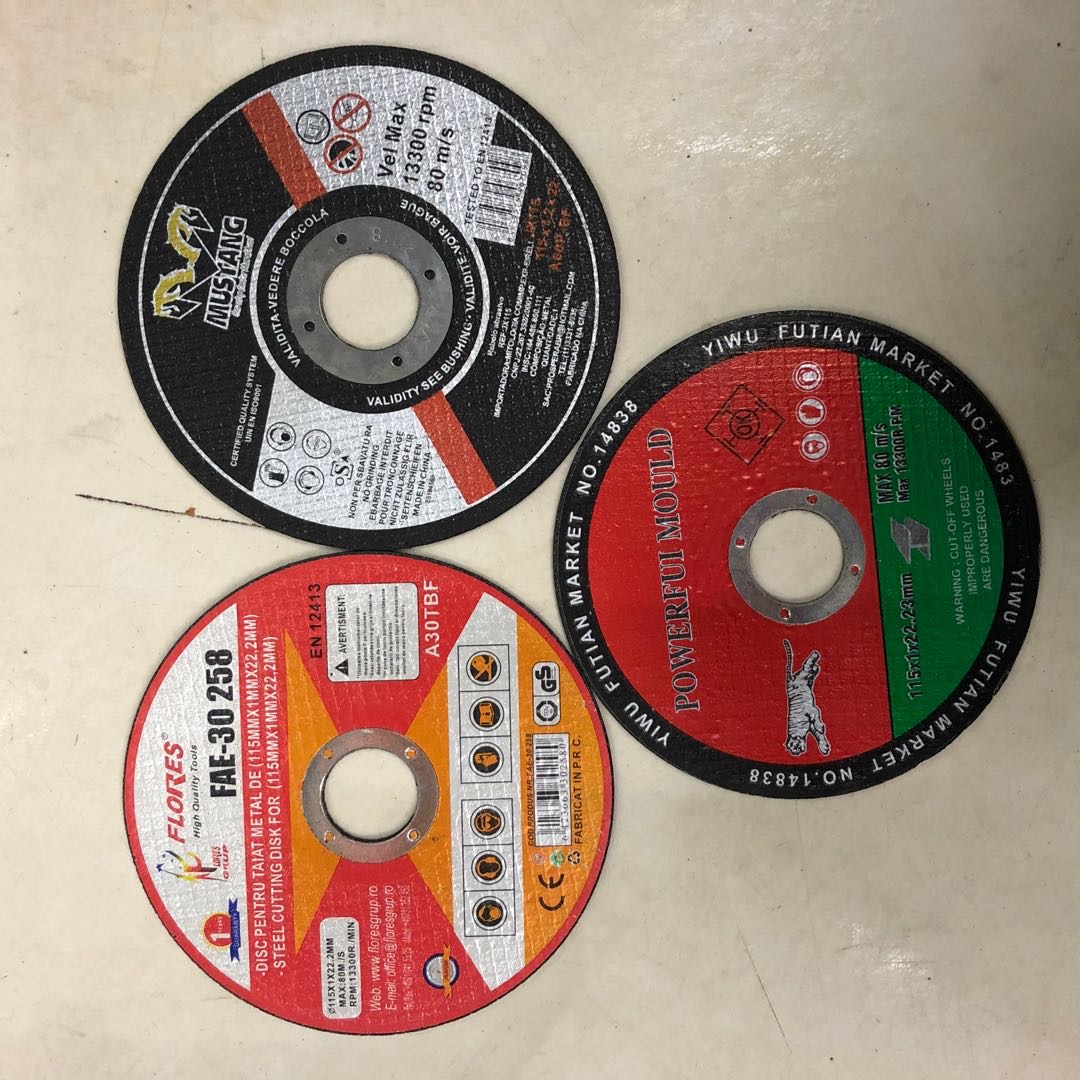

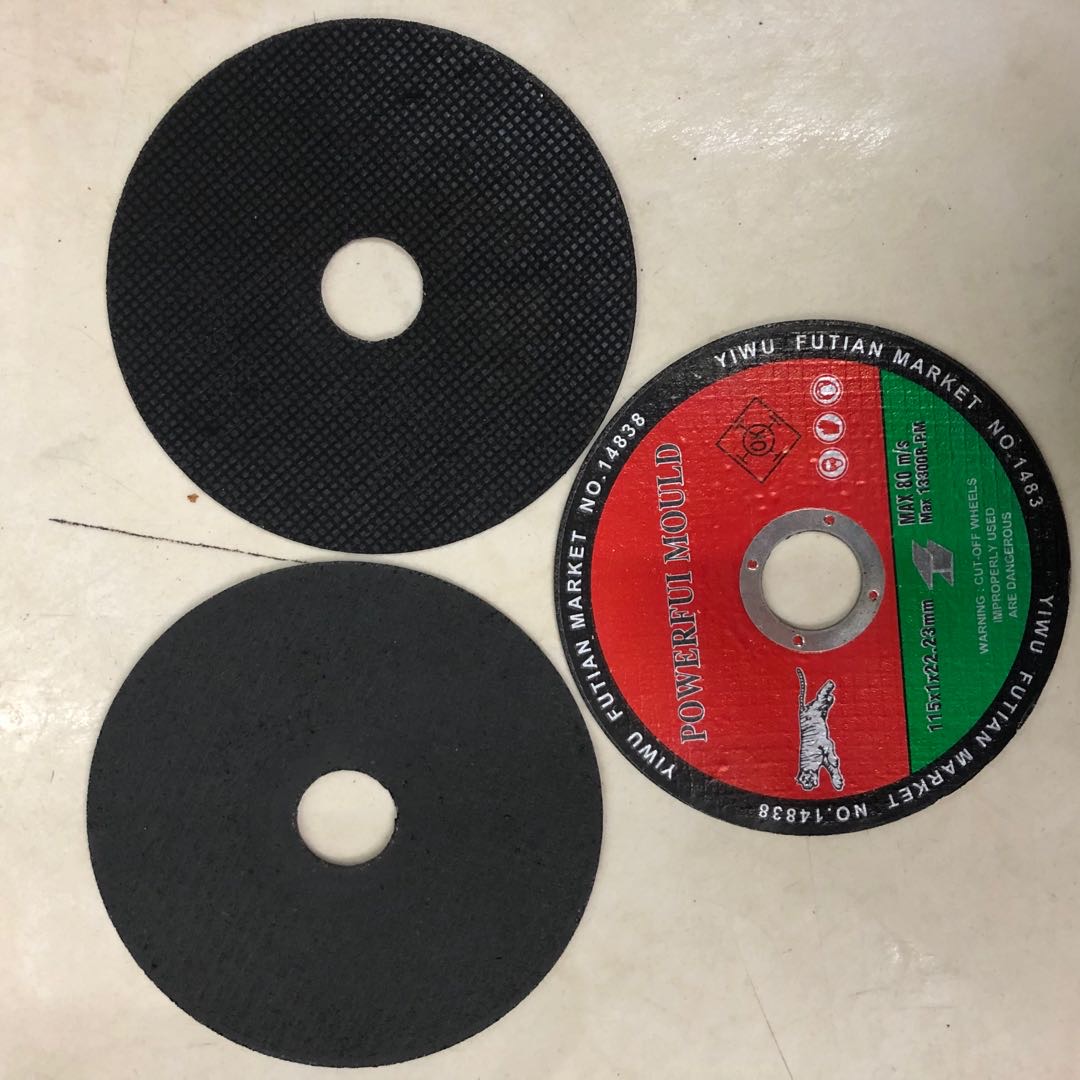

Multi-angle comparison: the actual performance difference of traditional grinding wheel plate vs ultra-thin cutting plate

Compared with the traditional thick grinding wheel plate, the advantages of ultra-thin cutting plate are obvious. First of all, due to its slim design, it is more convenient and flexible to operate in a narrow space; secondly, due to its reduced weight, it will not feel tired after long-term use. In addition, thanks to more sophisticated edge control technology, the incision is smooth and tidy, reducing the time cost of the subsequent finishing process.

Application Scenario Details: All-round Assistant from Building Construction to Artwork Polishing

This ultra-thin cutting board is not limited to a specific field. Whether the construction site needs to quickly and accurately divide the reinforced concrete structural parts, or the handicraft production process requires meticulous hand carving, you can rely on this artifact to achieve the ideal effect. Every nuance has been carefully crafted to meet the diverse needs of users in different industries.

How to install and debug correctly? Mastering these tips will help you get twice the result with half the effort

In order to give full play to the maximum potential of the ultra-thin cutting board, be sure to follow the correct steps for assembly and debugging. The first step is to confirm whether the rotation speed of the angle grinder used matches the specified range; the second step is to check whether the fixing nut is loose to prevent accidents. Finally, don't forget to wear protective gear for personal safety.

Advanced Tutorial: Accurate Machining of Complex Curved Surface with Ultra-thin Cutting Board

As technology continues to improve, many users are trying to challenge more difficult tasks-such as precise cutting on curved surfaces. At this time, the task can be successfully completed only by properly adjusting the tilt angle and matching the smooth movement gesture. Remember to always keep the pace of advancing helps to get a better finished product quality.

Maintenance strategy: a small coup to extend the service life should not be missed

Although the ultra-thin cutting board itself has strong durable properties, it is still recommended to clean it regularly to maintain good condition. At the same time, avoid contact with moisture to avoid unnecessary oxidation problems. Following the above method can significantly delay the wear rate and thus obtain more value return.