In all kinds of metal processing and stone processing work scene, a high quality grinding wheel plate is undoubtedly an important tool to improve efficiency. Today, we will delve into the core values of ultra-thin cutting plates and multifunctional polishing plates for angle grinders, and show you why they are ideal for many professionals.

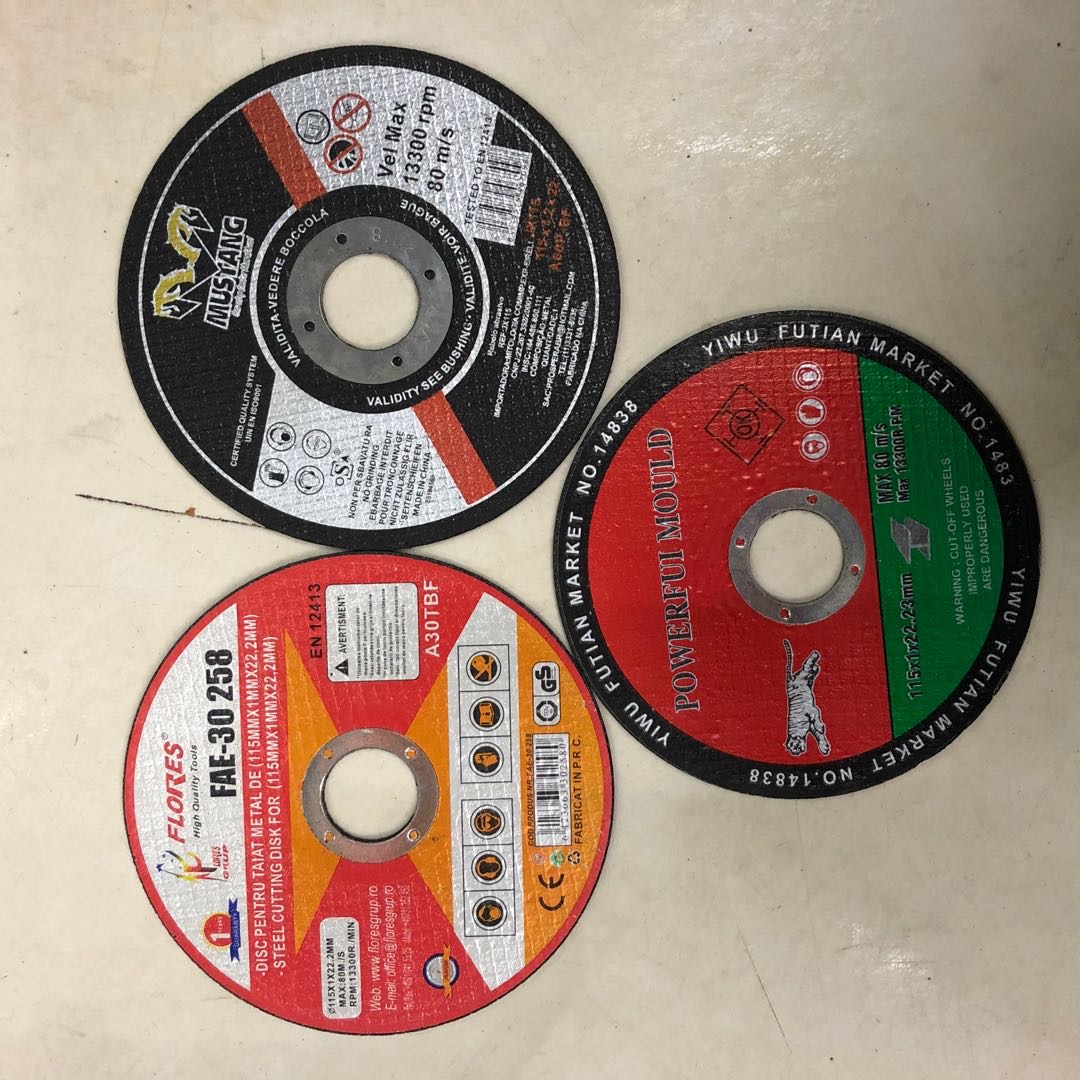

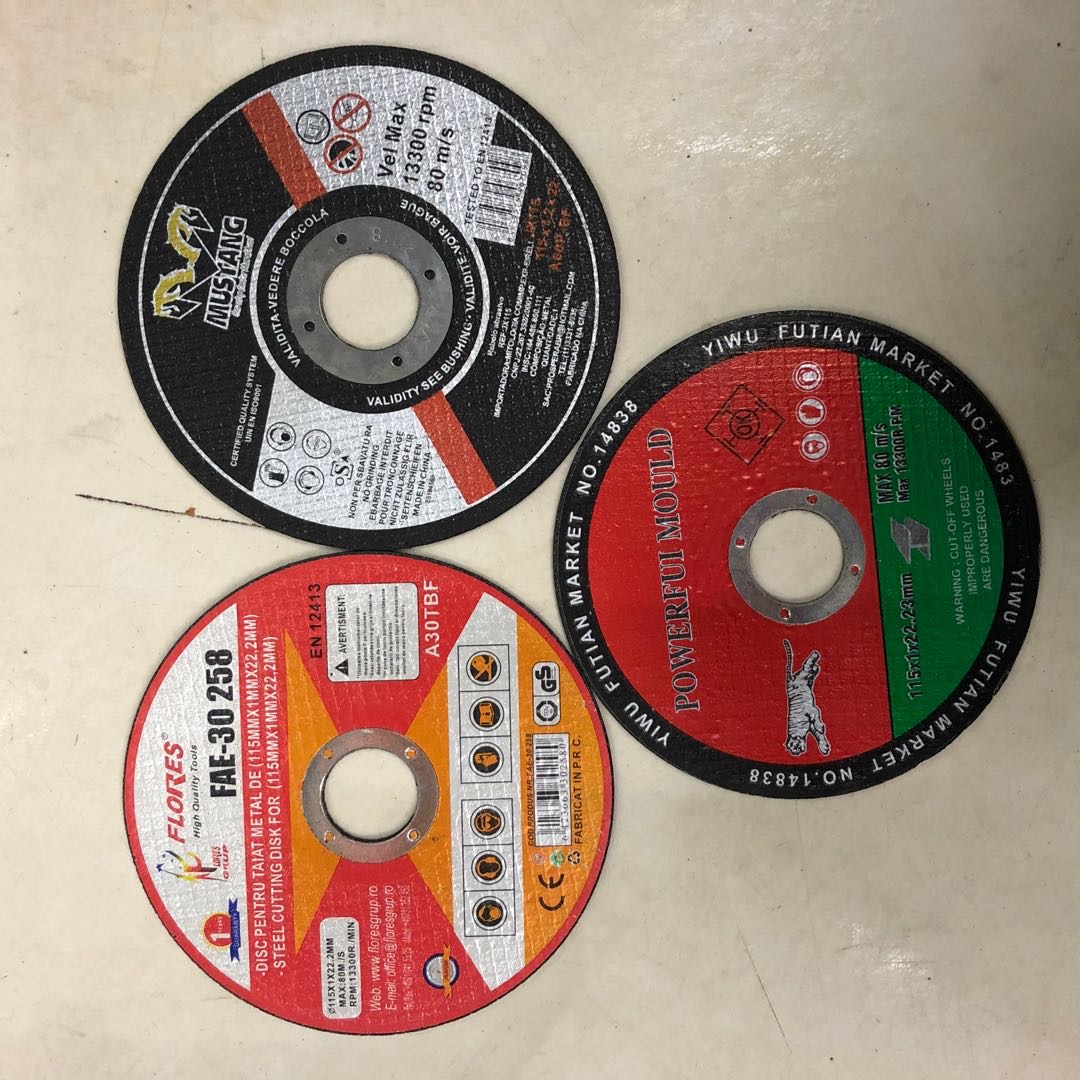

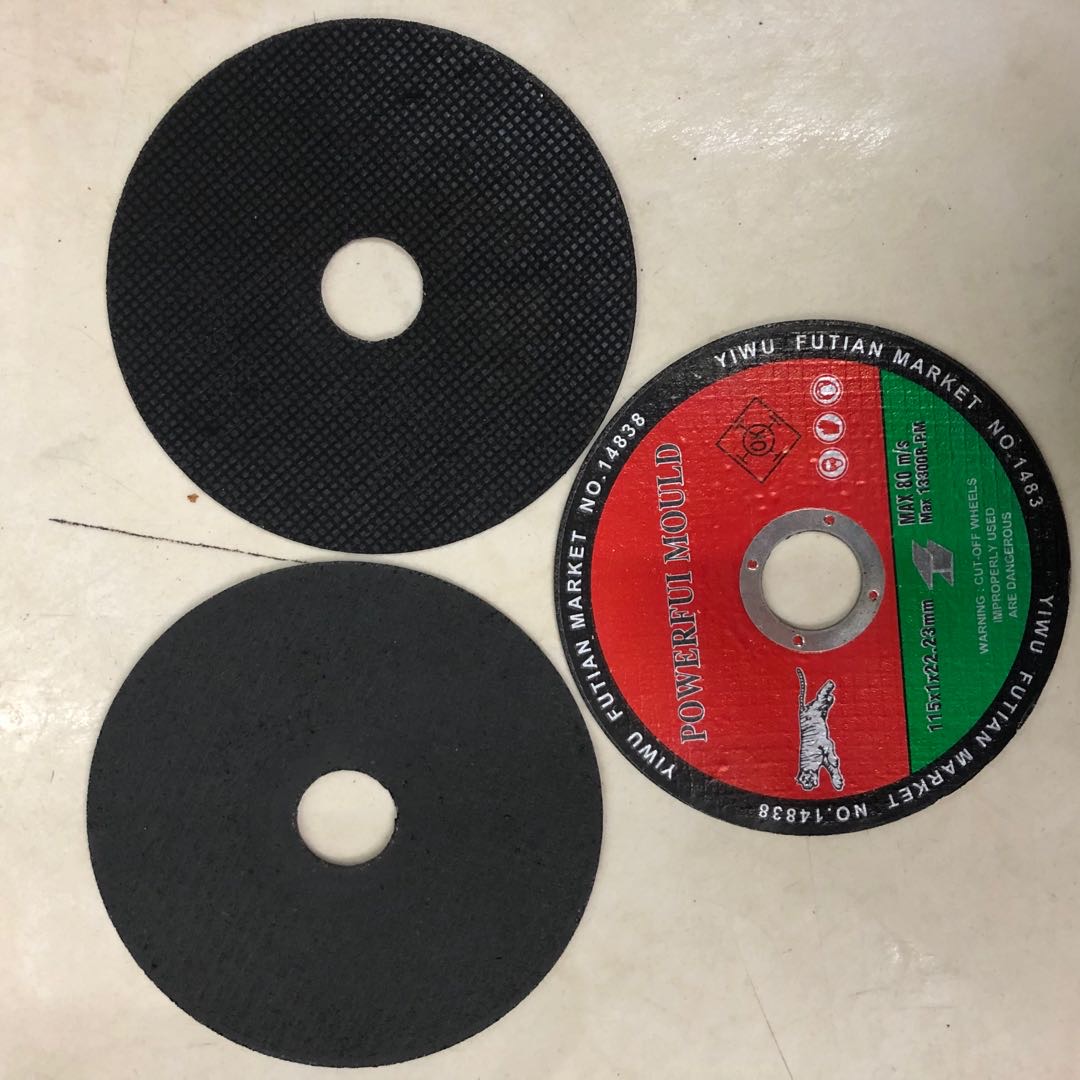

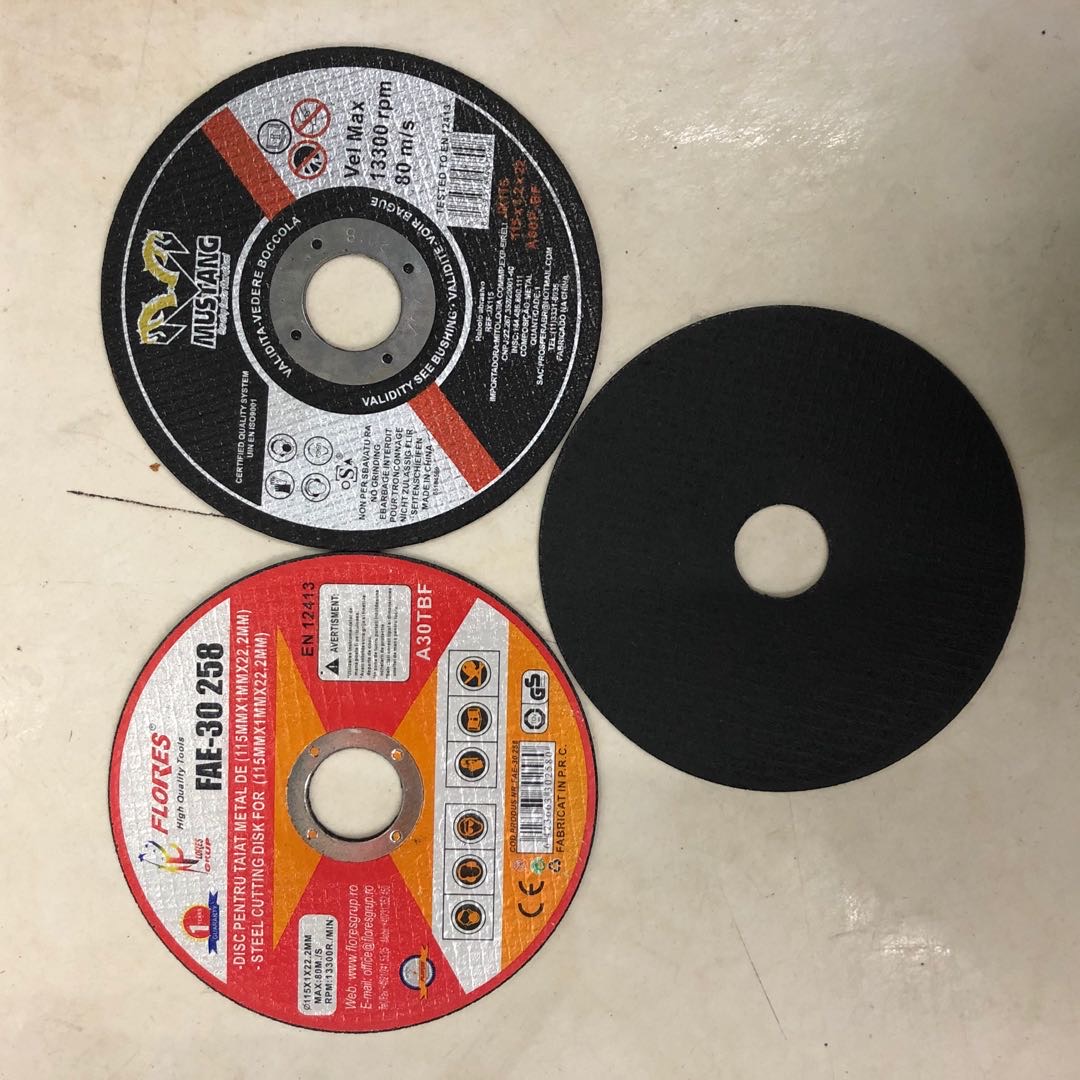

First look at the ultra-thin cutting board, its uniqueness makes it stand out in the market. Compared with the traditional thick cutting blade, the ultra-thin design greatly reduces the material loss and improves the accuracy. Especially in the narrow space or fine operation, ultra-thin cutting board shows an unparalleled advantage. In addition, the high-strength material ensures the stability of long-term use, making you more confident every time you cut.

On the other hand, the multi-function polishing plate is also not to be underestimated. It not only can achieve a variety of surface treatment effects, such as mirror polishing, matte texture, etc., but also can be applied to different substrate types, including stainless steel, aluminum alloy and even glass ceramic products. This ability to adapt flexibly allows a small polishing plate to easily cope with a variety of tasks.

However, in front of a dazzling array of market choices, it is not easy to choose a grinding wheel plate suitable for your work. First of all, it is necessary to make clear whether the specific application scenario is rough grinding or precision cutting. Secondly, it is necessary to consider personal operating habits and whether the equipment power matches the selected product specifications. Finally, don't ignore the importance of brand reputation and technical support services, because this often determines the cost of follow-up maintenance.

In addition to the right choice, reasonable use methods are also essential. It is suggested that novice friends should be familiar with the running state of the machine before making practical attempts. In addition, pay attention to wearing necessary protective equipment such as goggles and gloves to ensure the first principle of safety. There is also the regular inspection and replacement of severely worn parts to avoid accidents causing losses and increasing risks.

Many customers who have purchased and tried these products have given positive feedback. "I used to worry that ordinary cutter heads would get stuck and cause damage to the workpiece. Now this ultra-thin model has completely solved my troubles!" A long-term engaged in the car repair industry master said. Another craftsman in the field of home decoration said: "The polishing effect is great! Even a large area that is difficult to do can be done at once, saving a lot of time and energy."

In short, whether it is the pursuit of the ultimate accuracy of the industrial manufacturing field, or focus on beautiful and practical home DIY projects, with a set of high-performance angle grinder accessories are essential good helper. I hope that today's sharing can help you better understand these two types of star tools, and play a greater potential in the future work!